Arctic Gas Trade Reliant On European Shipyard Capacity

Table of Contents

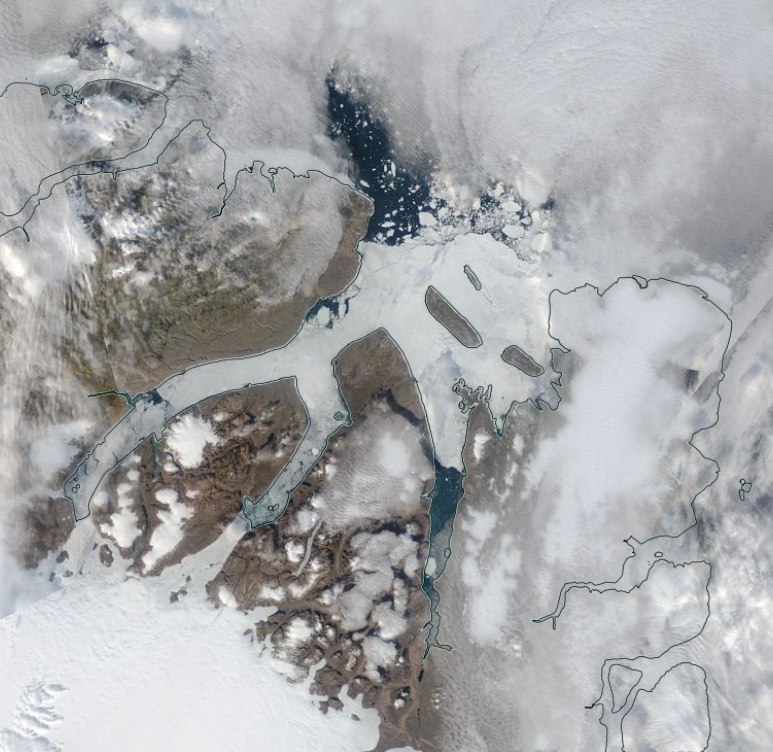

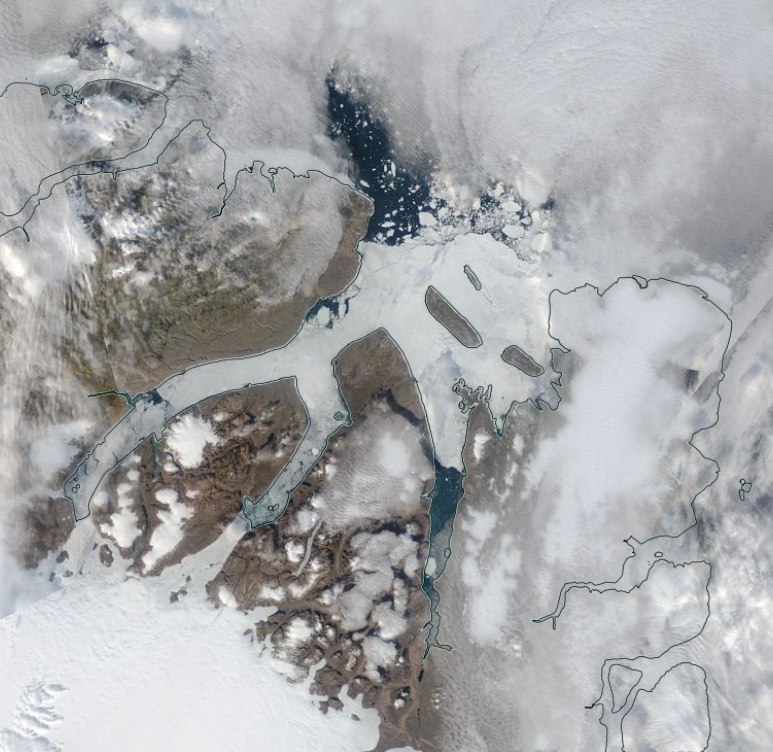

The Unique Demands of Arctic LNG Shipping

Arctic shipping presents unparalleled challenges. Navigating icy waters, enduring extreme temperatures, and operating in remote locations requires vessels far beyond the capabilities of standard LNG carriers. The harsh environment necessitates robust design and advanced technology.

- Ice Conditions: Arctic ice presents a significant obstacle, demanding specialized ice-class hulls. Vessels operating in these regions must be capable of breaking through thick ice floes, requiring reinforced hulls and powerful propulsion systems. Ice class specifications, such as Polar Class 7, are essential for safe operation in the most challenging ice conditions.

- Extreme Temperatures: Sub-zero temperatures impact every aspect of vessel operation, from the performance of machinery to the integrity of materials. Special considerations are required for fuel storage, lubrication systems, and crew comfort.

- Specialized Vessel Requirements: Arctic LNG carriers need advanced features not found in conventional vessels. This includes:

- Ice-Class Hulls: Reinforced hulls designed to withstand the pressures of ice impact.

- Advanced Propulsion Systems: Powerful engines and propellers capable of breaking ice and maintaining speed in challenging conditions. Fuel efficiency is paramount to reduce operational costs and environmental impact.

- Robust Safety Features: Redundant systems, advanced navigation technology, and robust safety protocols are vital due to the remoteness of operating areas and potential rescue challenges.

- Advanced Navigation and Communication Systems: Reliable satellite communication and sophisticated navigation systems are essential given the lack of infrastructure in the Arctic.

European Shipyards: A Crucial Role in Arctic Gas Development

European shipyards possess the technological expertise and experience to build and maintain the specialized LNG carriers needed for Arctic gas development. They are at the forefront of developing and implementing innovative technologies required for Arctic operations.

- Leading Shipyards: Several European shipyards, renowned for their shipbuilding prowess, are leading the charge in constructing Arctic-capable vessels. Their experience in building complex LNG carriers, coupled with their understanding of ice-class requirements, positions them uniquely to meet this growing demand.

- Technological Advantages: European shipyards consistently push the boundaries of shipbuilding technology, incorporating advanced materials, optimized hull designs, and fuel-efficient propulsion systems to improve the performance and environmental friendliness of Arctic LNG carriers.

- Successful Projects: These yards have already delivered several successful Arctic LNG carrier projects, demonstrating their ability to meet the stringent demands of this challenging environment. These successes showcase their technological capabilities and commitment to safety.

- Economic Benefits: The construction and maintenance of Arctic LNG carriers generate significant economic benefits for European countries, creating jobs and stimulating innovation within the shipbuilding and related industries.

Capacity Constraints and Bottlenecks

While European shipyards play a vital role, capacity constraints and potential bottlenecks could hinder the industry's growth.

- Order Books and Lead Times: The current order books of European shipyards indicate a substantial demand for Arctic LNG carriers, potentially leading to extended lead times and capacity constraints.

- Skilled Labor Shortages: A shortage of skilled welders, engineers, and other specialized labor could slow down construction.

- Infrastructure Limitations: Existing shipyard infrastructure may need upgrades to handle the increased demand and the specific requirements of Arctic LNG carrier construction.

- Supply Chain Challenges: Securing specialized materials and components for these vessels could present logistical challenges, potentially leading to delays.

- Environmental Regulations: Stricter environmental regulations might increase construction costs and lead times, impacting the overall feasibility of Arctic gas projects.

Geopolitical Implications and Future Outlook

Europe's central role in Arctic gas trade carries significant geopolitical implications. The future of this industry hinges on several factors.

- Geopolitical Tensions: Geopolitical instability in the Arctic region could disrupt access to resources and shipping routes, creating uncertainty in the market.

- Technological Advancements: Continued advancements in shipbuilding technology, such as the development of more efficient and environmentally friendly propulsion systems, could alleviate some of the capacity constraints.

- Alternative Shipbuilding Locations: While Europe currently holds a dominant position, the potential emergence of alternative shipbuilding locations capable of constructing Arctic LNG carriers could reshape the industry landscape.

- International Collaborations: International cooperation is crucial for sustainable and responsible development of Arctic gas resources, requiring collaborative efforts in regulating shipping, protecting the environment, and ensuring safe operations.

Conclusion

The role of European shipyards in enabling Arctic gas trade is undeniable. The unique demands of Arctic shipping, from ice-class hulls to advanced propulsion systems, necessitate specialized shipbuilding expertise. While challenges exist, including capacity constraints and potential bottlenecks, the future outlook remains positive due to the potential for technological innovation and international collaboration. Understanding the crucial link between Arctic gas trade reliant on European shipyard capacity is vital for future energy security. To learn more, explore resources from organizations like the International Maritime Organization (IMO) and various European shipbuilding associations.

Featured Posts

-

The Countrys Booming Business Regions A Location Guide

Apr 26, 2025

The Countrys Booming Business Regions A Location Guide

Apr 26, 2025 -

Nepo Babies Inherited Fame And The Oscars After Party Debate

Apr 26, 2025

Nepo Babies Inherited Fame And The Oscars After Party Debate

Apr 26, 2025 -

Gambling On Catastrophe The Los Angeles Wildfires And The Future Of Risk

Apr 26, 2025

Gambling On Catastrophe The Los Angeles Wildfires And The Future Of Risk

Apr 26, 2025 -

Sinners How Cinematography Showcases The Mississippi Deltas Expansiveness

Apr 26, 2025

Sinners How Cinematography Showcases The Mississippi Deltas Expansiveness

Apr 26, 2025 -

Military Base In The Pacific A Focal Point Of Us China Strategic Competition

Apr 26, 2025

Military Base In The Pacific A Focal Point Of Us China Strategic Competition

Apr 26, 2025