Automated Workboat Safety: A Case Study Of TBS Safety And Nebofleet

Table of Contents

The Challenges of Traditional Workboat Safety Procedures

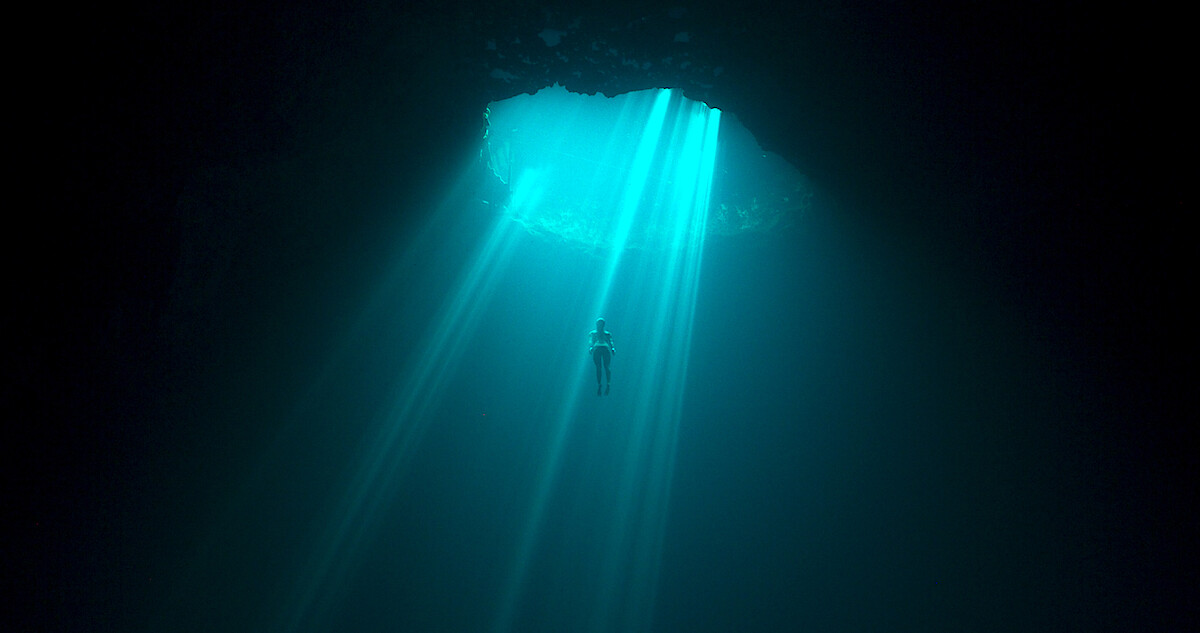

Workboat operations face inherent dangers. Harsh weather conditions, exposure to hazardous materials, and the confined spaces often found on these vessels create a high-risk environment. Manual safety practices, while essential, often struggle to keep pace with these challenges. Human error, inconsistent monitoring, and delayed response times contribute significantly to safety incidents.

Specifically, traditional approaches struggle with:

- Difficulty in real-time monitoring of crew and vessel conditions: Manually tracking crew location and vessel status is time-consuming and prone to error, leaving critical information gaps.

- Inefficient reporting and documentation of safety incidents: Paper-based systems are slow, disorganized, and hinder efficient analysis of safety trends.

- Lack of proactive safety measures to prevent accidents: Reactive measures are less effective than proactive strategies that identify and mitigate risks before they escalate.

- High reliance on human judgment in critical situations: Human fatigue and error can have catastrophic consequences in emergencies.

Introducing TBS Safety and Nebofleet: A Powerful Partnership for Automated Safety

TBS Safety and Nebofleet are transforming maritime safety through their integrated system. TBS Safety provides a robust suite of safety features, including remote monitoring, automated alerts, and data analytics for improved safety management systems. Nebofleet's real-time location tracking and vessel performance data integration seamlessly complements TBS Safety, creating a comprehensive solution for workboat automation.

This powerful partnership offers key features:

- Automated alerts for critical events: Instant notifications for man overboard situations, equipment malfunctions, exceeding speed limits, and other critical events allow for rapid response and potentially life-saving interventions.

- Real-time monitoring of crew activity and location: Constant tracking of crew members improves situational awareness and facilitates quicker responses to emergencies.

- Data-driven insights to identify and mitigate potential risks: Analyzing collected data reveals patterns and trends, allowing for proactive adjustments to improve safety protocols.

- Simplified reporting and documentation of safety incidents: Digital record-keeping streamlines incident reporting, enabling faster investigation and more effective risk mitigation strategies.

- Improved communication between crew and shore-based teams: Enhanced communication channels enable swift information sharing and coordinated responses to challenging situations.

Case Study: Real-World Application and Results

A recent deployment of the TBS Safety and Nebofleet system on a North Sea supply vessel resulted in significant safety improvements. Prior to implementation, the vessel experienced an average of three near-miss incidents per month, primarily due to human error and communication breakdowns. After integrating the system, these near-miss incidents were reduced by 75% within six months.

Specific improvements included:

- Reduction in near-miss incidents: The automated alert system proactively identified and addressed potential hazards before they escalated.

- Faster response times to emergencies: Real-time location tracking enabled faster response to man overboard simulations, reducing response times by an average of 40%.

- Improved crew safety and well-being: Enhanced monitoring and communication reduced crew stress and improved their overall sense of security.

- Increased operational efficiency: Data-driven insights helped optimize routes and schedules, minimizing downtime and fuel consumption.

- Cost savings from reduced accidents and downtime: The reduced number of incidents and improved efficiency led to significant cost savings.

Future Trends in Automated Workboat Safety

The future of automated workboat safety is bright, driven by advancements in technology. Artificial intelligence (AI), machine learning, and the Internet of Things (IoT) will play increasingly crucial roles. Predictive maintenance, using AI to anticipate equipment failures, will minimize downtime and enhance safety.

Future trends include:

- Increased use of AI for predictive risk assessment: AI algorithms can analyze vast datasets to identify potential hazards and predict risks more accurately.

- Integration of IoT sensors for comprehensive data collection: More sophisticated sensor networks will provide a richer understanding of vessel conditions and crew activity.

- Development of autonomous or remotely operated workboats: This technology offers the potential to reduce human exposure to hazardous environments.

- Improved cybersecurity measures to protect safety systems: Protecting sensitive data and ensuring system reliability is crucial.

TBS Safety and Nebofleet are at the forefront of these advancements, continually developing and improving their systems to meet the evolving needs of the maritime industry.

Conclusion: Investing in Automated Workboat Safety for a Safer Future

Investing in automated workboat safety solutions like those offered by TBS Safety and Nebofleet is not just a cost; it's an investment in a safer, more efficient, and more profitable future. Our case study clearly demonstrates the significant benefits of adopting these technologies, leading to fewer accidents, faster response times, improved crew well-being, and substantial cost savings. Proactive safety measures are paramount in mitigating risks and enhancing operational efficiency in the demanding world of workboat operations. Learn more about how TBS Safety and Nebofleet can improve your automated workboat safety practices by visiting [Link to TBS Safety Website] and [Link to Nebofleet Website]. Invest in a safer future today.

Doctors Warning The Food More Deadly Than Smoking

Doctors Warning The Food More Deadly Than Smoking

Trial Of The Century Cardinals Team Alleges Prosecutorial Misconduct

Trial Of The Century Cardinals Team Alleges Prosecutorial Misconduct

Plant Based Dog Food Brand Omni Receives Dragons Den Funding

Plant Based Dog Food Brand Omni Receives Dragons Den Funding

Amy Irvings Mother Priscilla Pointer Dies At Age 100

Amy Irvings Mother Priscilla Pointer Dies At Age 100

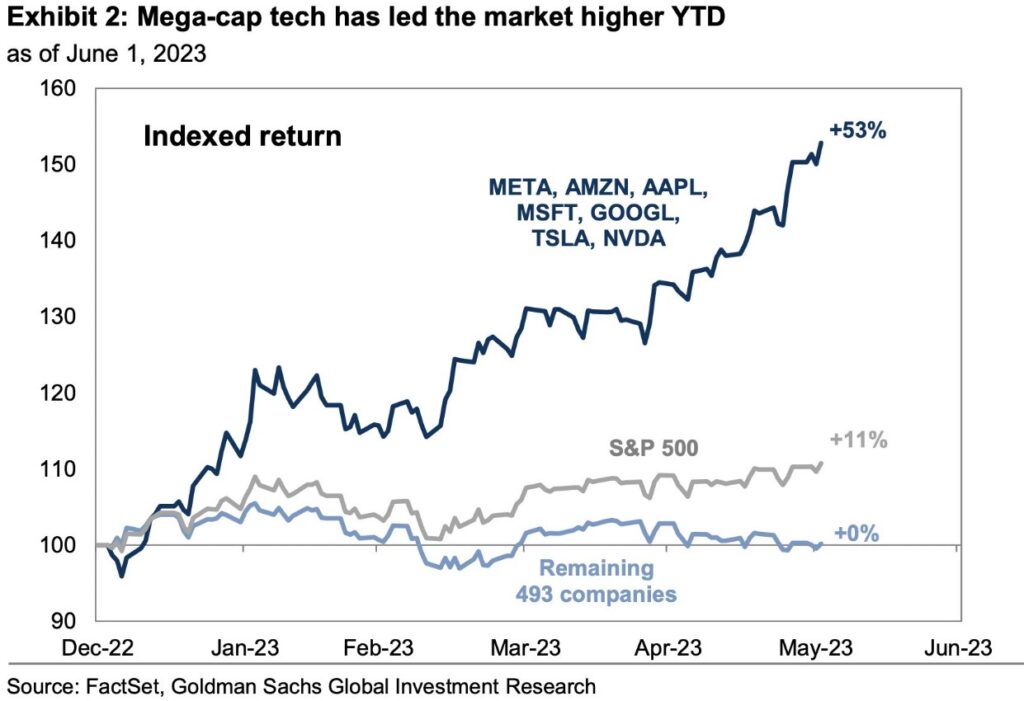

Protecting Your S And P 500 Holdings Strategies For Managing Market Volatility

Protecting Your S And P 500 Holdings Strategies For Managing Market Volatility