Big Rig Rock Report 3.12: Rock 101 Insights And Data

Table of Contents

Understanding Rock Strength and its Implications

Rock strength, a fundamental property in rock mechanics, dictates a material's ability to resist deformation and failure under applied stress. This understanding is crucial in various applications, influencing design parameters, safety protocols, and overall project feasibility. Different methods exist to determine rock strength, each providing valuable information relevant to specific engineering needs.

- Uniaxial Compressive Strength (UCS): This widely used method measures the maximum compressive stress a rock sample can withstand before failure. UCS testing procedures are standardized to ensure reliable results, critical for informing design decisions.

- Tensile Strength: This parameter assesses the rock's ability to resist pulling forces, crucial for applications involving tensile stresses, such as rock bolting or anchoring.

- Factors influencing rock strength: Several factors contribute to the overall rock strength, including mineralogical composition, the presence of discontinuities (joints, fractures), and the prevailing in-situ stress state. These factors must be considered when interpreting rock strength data.

- Correlation with other properties: UCS often correlates with other rock properties, such as elasticity and durability, allowing engineers to predict overall rock mass behavior.

- Case studies: Big Rig Rock Report 3.12 features compelling case studies illustrating how accurate rock strength data directly impacts project success or failure. Poorly characterized rock strength has led to slope instability, tunnel collapses, and equipment damage, highlighting the importance of robust testing and analysis.

Rock Mass Classification Systems: A Comprehensive Overview

Effective rock mass classification is essential for predicting the behavior of rock masses in engineering projects. Several systems categorize rock masses based on various parameters, providing a quantitative assessment of rock mass quality and stability.

- RMR (Rock Mass Rating): The RMR system considers factors like rock strength, spacing of discontinuities, groundwater conditions, and in-situ stress, providing a rating used for design and stability assessments.

- Q-system: This system uses a more complex formula incorporating parameters such as UCS, joint roughness, and groundwater conditions, offering a more nuanced classification.

- Geological Strength Index (GSI): GSI is a visually-based system incorporating the rock's structure and the condition of its discontinuities, often used in numerical modeling for more complex situations.

- Choosing the right system: The selection of a suitable classification system depends on the project's specifics, the available data, and the desired level of detail in the analysis. Big Rig Rock Report 3.12 provides a detailed comparison of these systems, guiding users towards the best choice.

Analyzing Geological Data for Informed Decision-Making

Accurate and reliable geological data forms the foundation of successful rock engineering projects. Various data acquisition methods are employed to characterize the rock mass and its properties.

- Core logging: Detailed core logging provides essential information about lithology, structure, and the presence of discontinuities. This information is directly used for characterizing the rock mass.

- Geophysical surveys: Geophysical techniques like seismic surveys and resistivity measurements offer valuable data on subsurface geology, often extending the information obtained from drilling and core logging.

- Data visualization: Big Rig Rock Report 3.12 leverages advanced data visualization techniques, allowing for easier interpretation of complex geological data sets and facilitating better communication with stakeholders.

- Statistical analysis: Statistical analysis of the data allows for a better understanding of variability and uncertainty, critical for risk assessment and decision-making. This is highlighted throughout the report.

Practical Applications and Case Studies

Big Rig Rock Report 3.12 isn't just theory; it's packed with real-world applications and case studies that demonstrate the practical impact of accurate rock mechanics understanding.

- Case Study 1: A mining project successfully used the report's data to optimize blast designs, resulting in improved fragmentation and reduced operating costs.

- Case Study 2: A construction project used the report’s insights to identify and mitigate potential geological hazards, preventing costly delays and ensuring worker safety.

- Case Study 3: By leveraging the report's findings, a tunneling project achieved significant efficiency gains and cost savings due to improved ground support design.

Conclusion: Leverage Big Rig Rock Report 3.12 for Superior Rock Mechanics Understanding

In conclusion, a strong grasp of rock mechanics is crucial for the success of any project involving rock masses. Big Rig Rock Report 3.12 serves as a comprehensive resource, providing essential data and insights into rock strength, rock mass classification, and geological data analysis. This report's practical applications and case studies highlight the value of accurate rock characterization in improving project outcomes, safety, and efficiency. Get your copy of the Big Rig Rock Report 3.12 today to improve your rock mechanics analysis and unlock the power of geological data! Enhance your understanding of rock properties and improve your project's success by accessing this invaluable resource. Unlock the power of Big Rig Rock Report 3.12 for superior rock mechanics understanding.

Felicidades Ganadores Del Sorteo De Entradas Para El Partido Cb Gran Canaria Unicaja

Felicidades Ganadores Del Sorteo De Entradas Para El Partido Cb Gran Canaria Unicaja

Ntyjt Mbarat Qtr Walkhwr Ebd Alqadr Yshark Fy Alkhsart

Ntyjt Mbarat Qtr Walkhwr Ebd Alqadr Yshark Fy Alkhsart

Joe Jonas Defuses Couples Argument His Response

Joe Jonas Defuses Couples Argument His Response

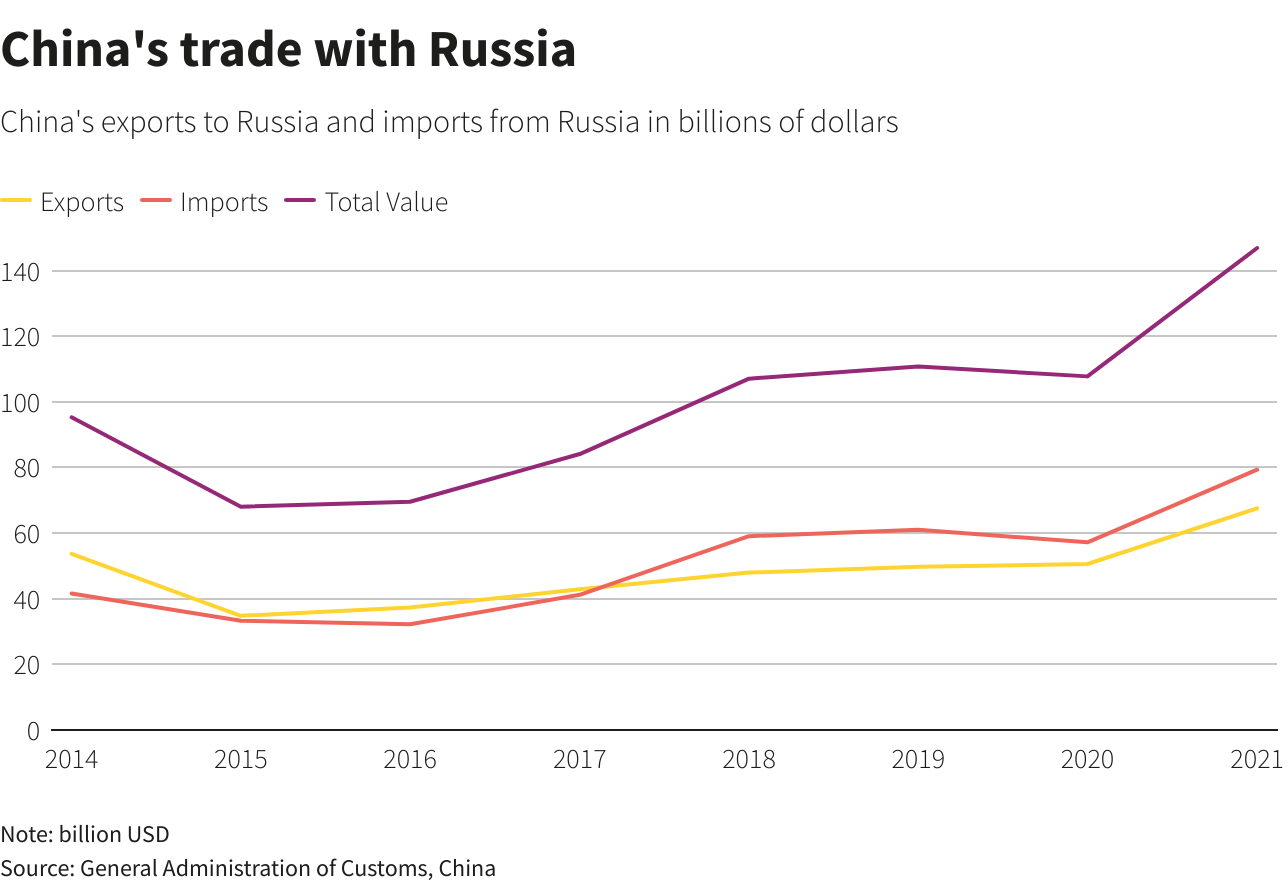

China And Us Trade Record Exports As Trade Deal Deadline Approaches

China And Us Trade Record Exports As Trade Deal Deadline Approaches

Posible Alineacion De Instituto Novedades Y Citados Para Enfrentar A Lanus

Posible Alineacion De Instituto Novedades Y Citados Para Enfrentar A Lanus