BYD's EV Battery Dominance: A Case Study Addendum

Table of Contents

BYD's Technological Breakthroughs: The Blade Battery and Beyond

BYD's technological prowess is perhaps best exemplified by its groundbreaking Blade Battery. This innovative battery design represents a significant advancement over traditional battery packs, offering several key advantages that have disrupted the EV battery landscape.

-

Higher Energy Density: The Blade Battery boasts a significantly higher energy density compared to traditional lithium-ion batteries, allowing for longer driving ranges on a single charge. This is crucial for enhancing the appeal and practicality of electric vehicles.

-

Improved Safety Features: The Blade Battery's unique design minimizes the risk of thermal runaway, a major safety concern with some battery technologies. Its robust structure and inherent design contribute to enhanced safety for both drivers and passengers.

-

Cost-Effectiveness: BYD's advanced manufacturing processes and optimized design contribute to the cost-effectiveness of the Blade Battery, making it a more accessible and competitive option compared to some rival technologies.

-

Space-Saving Design: The Blade Battery's sleek, blade-like form factor allows for more efficient use of space within the vehicle chassis, contributing to improved vehicle design and interior space.

-

Compatibility with Various EV Models: The Blade Battery's adaptability makes it suitable for integration into a wide range of BYD's EV models, demonstrating its versatility and scalability.

Beyond the Blade Battery, BYD continues to invest heavily in research and development, exploring other advanced battery technologies and chemistries, including further advancements in lithium iron phosphate (LFP) batteries, to maintain its competitive edge in the ever-evolving EV battery market. This commitment to continuous innovation ensures BYD remains at the cutting edge of EV battery technology advancements, continually improving energy density, battery safety, and overall performance.

Vertical Integration: Control Over the Entire Supply Chain

A cornerstone of BYD's success is its strategy of vertical integration within the EV battery production process. This comprehensive approach encompasses every stage, from securing raw materials to final manufacturing and distribution.

-

Control Over Raw Materials: BYD actively manages its supply chain, ensuring a consistent and secure supply of essential raw materials needed for battery production. This reduces reliance on external suppliers and mitigates potential disruptions.

-

Efficient Manufacturing Processes: By controlling the entire process, BYD optimizes manufacturing efficiency, reducing production costs and improving overall output. This integrated approach ensures quality control at every stage.

-

Reduced Reliance on External Suppliers: Vertical integration minimizes dependence on external suppliers, reducing risks associated with price fluctuations, supply chain bottlenecks, and potential geopolitical uncertainties.

-

Cost Optimization: Streamlining the entire process from raw material sourcing to distribution results in significant cost advantages, allowing BYD to offer highly competitive battery pricing.

-

Faster Response to Market Demands: This integrated model enables BYD to respond more swiftly to changes in market demand and technological advancements, providing greater flexibility and adaptability.

This vertical integration strategy provides a significant competitive advantage over companies reliant on external suppliers, ensuring greater control, efficiency, and cost-effectiveness throughout the entire EV battery supply chain.

Strategic Partnerships and Market Expansion

BYD's global reach and market dominance are also a result of strategic partnerships and collaborations. These alliances have been instrumental in expanding their market influence and penetration.

-

Partnerships with Automakers: BYD collaborates with numerous prominent automakers globally, supplying them with its advanced EV batteries, significantly expanding its market reach.

-

Collaborations with Technology Companies: BYD actively seeks collaborations with technology firms to enhance battery technology and integrate it into broader EV ecosystems.

-

Government Initiatives and Subsidies: Government support and subsidies in various countries have played a vital role in supporting BYD's market expansion and encouraging the adoption of its EV technologies.

-

Expansion into New Geographical Markets: BYD continuously expands into new geographical markets, establishing a robust global presence and solidifying its position as a leading EV battery supplier.

These strategic moves have collectively contributed to BYD's significant market penetration, solidifying its place as a dominant force in the global EV market and accelerating the transition towards sustainable transportation.

Sustainable Practices and Environmental Responsibility

BYD is deeply committed to environmentally responsible manufacturing and the development of eco-friendly battery technology. This commitment extends to all aspects of its operations.

-

Focus on Reducing Carbon Footprint: BYD actively works to minimize its environmental impact, implementing sustainable practices throughout its manufacturing processes to reduce its carbon footprint.

-

Responsible Sourcing of Raw Materials: The company emphasizes responsible sourcing of raw materials, ensuring ethical and sustainable procurement practices.

-

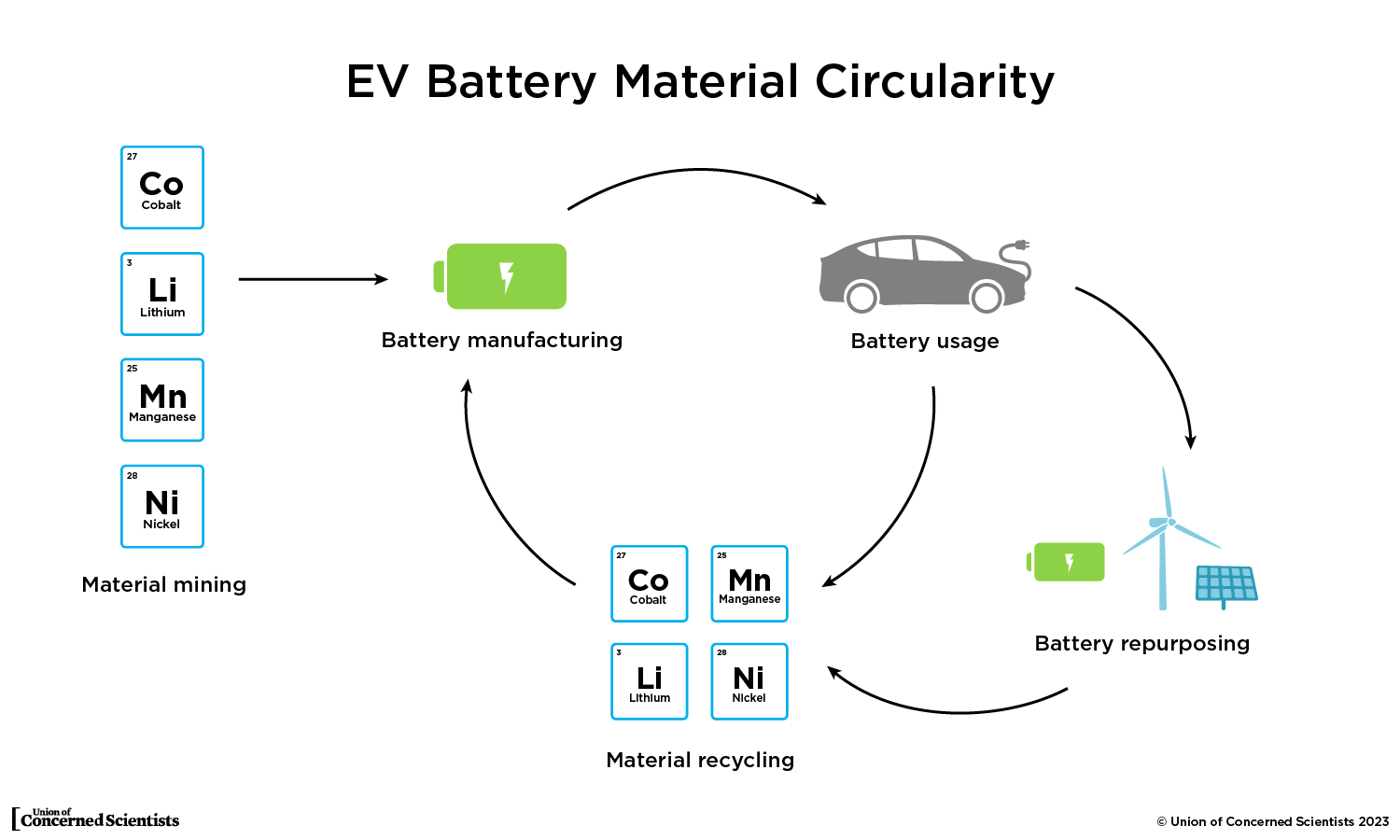

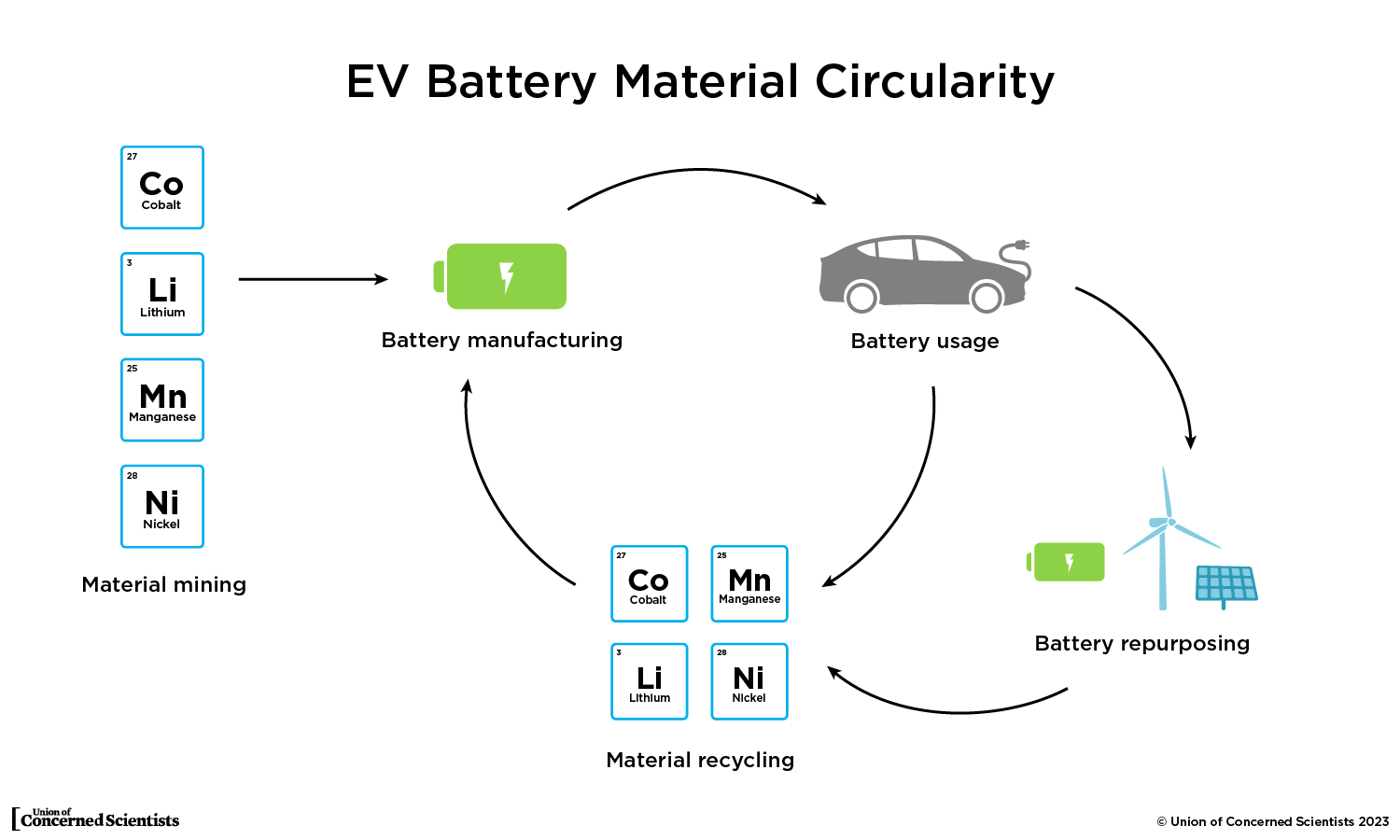

Recycling Initiatives: BYD is investing in advanced battery recycling technologies to minimize waste and promote a circular economy approach to battery production.

-

Commitment to Circular Economy Principles: BYD's dedication to the principles of the circular economy underscores its long-term commitment to sustainability and environmental stewardship.

This dedication to sustainability not only minimizes BYD's environmental impact but also significantly enhances its brand image and resonates strongly with environmentally conscious consumers, further driving market appeal and competitive advantage.

Conclusion

BYD's remarkable success in the EV battery market is the result of a meticulously planned strategy. Their commitment to technological innovation, particularly embodied in the Blade Battery technology, coupled with their efficient vertical integration, strategic partnerships, and unwavering focus on sustainability, has positioned them as a global leader. Their mastery of the entire EV battery supply chain, from raw materials to finished product, allows for cost advantages and efficient responses to market demands. To stay informed about the latest breakthroughs in BYD EV batteries and the evolving landscape of electric vehicle technology, keep following our blog for more in-depth analyses. Learn more about the future of BYD EV batteries and their impact on the global EV revolution.

Featured Posts

-

Earth Day May Day And Junior League Gala Your Community Highlights

May 13, 2025

Earth Day May Day And Junior League Gala Your Community Highlights

May 13, 2025 -

Colin Josts Lower Salary Compared To Scarlett Johansson A Closer Look

May 13, 2025

Colin Josts Lower Salary Compared To Scarlett Johansson A Closer Look

May 13, 2025 -

Leonardo Di Caprios Next 5 Films A Complete Guide

May 13, 2025

Leonardo Di Caprios Next 5 Films A Complete Guide

May 13, 2025 -

Prekmurski Romi In Njihova Muzikalna Dediscina Muzikanti Skozi Cas

May 13, 2025

Prekmurski Romi In Njihova Muzikalna Dediscina Muzikanti Skozi Cas

May 13, 2025 -

Ai Startup Alterya Acquired By Blockchain Giant Chainalysis

May 13, 2025

Ai Startup Alterya Acquired By Blockchain Giant Chainalysis

May 13, 2025