Enhanced Automated Visual Inspection For Lyophilized Vials: Tackling Common Problems

Table of Contents

1. Introduction

The visual inspection of lyophilized vials is crucial for ensuring product quality and patient safety. However, traditional manual methods are inherently flawed. Human inspectors face fatigue, leading to inconsistencies and missed defects. Subjectivity in assessment further complicates the process, resulting in higher error rates and potential product recalls. The demand for higher throughput in lyophilization manufacturing exacerbates these problems. Consequently, there's a growing need for reliable and efficient automated solutions. Enhanced automated visual inspection for lyophilized vials offers a compelling alternative, promising improved accuracy, efficiency, and regulatory compliance.

2. Main Points

H2: Identifying and Addressing Common Defects in Lyophilized Vials

H3: Visual Defects

Lyophilized vials can exhibit various visual defects that compromise product quality and regulatory compliance. These include:

- Cracks: Fractures in the vial glass, potentially leading to leakage and contamination.

- Particulate Matter: Visible particles within the vial, indicating contamination during manufacturing or filling.

- Discoloration: Changes in the product's color, suggesting degradation or chemical instability.

- Vial Damage: Physical damage to the vial, such as scratches or dents, compromising integrity.

- Incomplete Lyophilization: Uneven or incomplete freeze-drying, resulting in a non-uniform product.

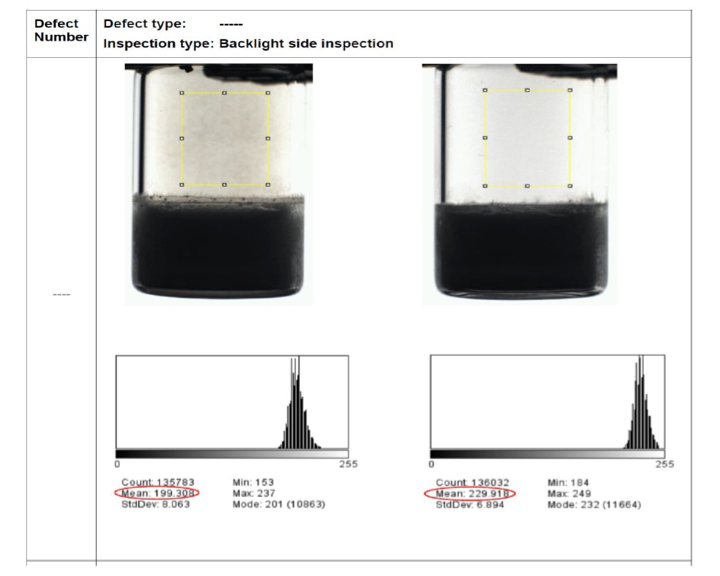

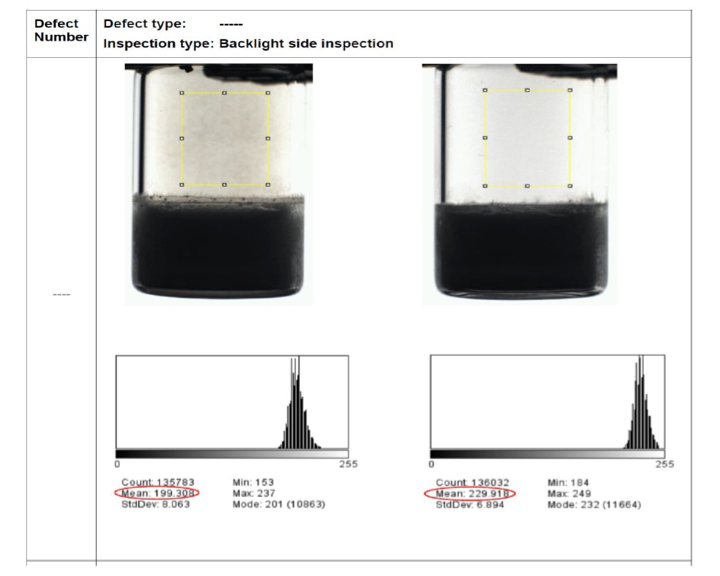

!

!

H3: Challenges in Manual Inspection

Manual visual inspection is inherently limited:

- Subjectivity: Human inspectors may interpret defects differently, leading to inconsistent results.

- Inconsistency: Fatigue and boredom can significantly reduce an inspector's accuracy over time.

- High Error Rate: Studies suggest manual inspection has error rates as high as 15-20%, leading to significant waste and potential recalls.

- Bottleneck: Manual inspection is slow, limiting production throughput and increasing lead times.

The financial impact of human error is significant, including wasted materials, rework, and the potential costs associated with product recalls.

H2: Advanced Technologies for Automated Visual Inspection

H3: Image Processing and Machine Learning

Automated visual inspection systems leverage advanced technologies to overcome the limitations of manual methods:

- High-Resolution Imaging: High-speed cameras capture detailed images of each vial, allowing for precise defect detection.

- AI-Powered Algorithms: Machine learning algorithms analyze images, identifying and classifying defects with high accuracy and consistency. These algorithms continuously learn and improve their performance.

- Data Analytics: The system collects and analyzes data, providing insights into defect trends, process optimization opportunities, and enabling predictive maintenance.

H3: System Components and Functionality

A typical automated visual inspection system comprises several key components:

- High-Speed Cameras: Capture multiple images of each vial from various angles.

- Advanced Lighting Systems: Optimize illumination for accurate defect detection.

- Robotic Handling: Automated vial handling and conveyance systems ensure efficient throughput.

- Sophisticated Software: Powerful software interfaces provide real-time defect analysis, reporting, and data management.

These systems boast impressive throughput capabilities, often inspecting thousands of vials per hour, and easily integrate with existing manufacturing lines.

H2: Benefits of Implementing Automated Visual Inspection

H3: Improved Accuracy and Consistency

Automated systems dramatically improve inspection accuracy and consistency:

- Reduced Human Error: Automation eliminates human subjectivity and fatigue-related errors.

- Increased Accuracy: Studies show a reduction in false positives and negatives by up to 80% compared to manual methods.

- Consistent Results: Every vial undergoes the same rigorous inspection process, ensuring consistent quality.

H3: Increased Throughput and Efficiency

Automation significantly boosts production efficiency:

- Higher Throughput: Automated systems can inspect significantly more vials per hour than manual methods.

- Reduced Inspection Time: Automated inspection is much faster, minimizing production bottlenecks.

- Improved Resource Allocation: Frees up human inspectors for other critical tasks.

H3: Enhanced Regulatory Compliance

Automated systems enhance regulatory compliance:

- Documented Evidence: The system provides complete, auditable records of every inspection.

- Reduced Recall Risk: Higher accuracy minimizes the risk of shipping defective products.

- Easier Audits: Automated systems simplify regulatory audits, demonstrating adherence to GMP and FDA guidelines.

H2: Choosing the Right Automated Visual Inspection System

H3: Factors to Consider

Selecting the right system requires careful consideration:

- Vial Size and Type: Ensure the system is compatible with your specific vial dimensions and materials.

- Throughput Requirements: Choose a system with sufficient capacity to meet your production needs.

- Budget Considerations: Balance cost with features and long-term benefits.

- Integration Capabilities: Confirm seamless integration with your existing manufacturing equipment.

- Regulatory Compliance: Verify that the system meets all relevant regulatory requirements.

H3: System Validation and Qualification

Rigorous validation and qualification are essential to ensure accuracy and regulatory compliance. This process verifies that the system performs as intended and meets predetermined specifications.

3. Conclusion

Enhanced automated visual inspection for lyophilized vials offers significant advantages over traditional manual methods. By improving accuracy, increasing efficiency, and ensuring regulatory compliance, these systems optimize lyophilization processes, leading to reduced costs and enhanced product quality. The benefits of implementing automated visual inspection far outweigh the initial investment, resulting in a substantial return on investment. To optimize your lyophilized vial production and enhance product quality, explore advanced Automated Lyophilized Vial Inspection Systems. Improve your Lyophilized Vial Inspection with Automation today! [Link to relevant products/services]

Featured Posts

-

Kya 62 Salh Tam Krwz Ne 36 Salh Adakarh Pr Dl Har Lya

May 11, 2025

Kya 62 Salh Tam Krwz Ne 36 Salh Adakarh Pr Dl Har Lya

May 11, 2025 -

April 17 20 Rays Vs Yankees Whos On The Injured List

May 11, 2025

April 17 20 Rays Vs Yankees Whos On The Injured List

May 11, 2025 -

National Fallen Firefighters Memorial A Tribute To Fremonts Bravest

May 11, 2025

National Fallen Firefighters Memorial A Tribute To Fremonts Bravest

May 11, 2025 -

White House Minimizes Auto Industrys Uk Trade Deal Concerns

May 11, 2025

White House Minimizes Auto Industrys Uk Trade Deal Concerns

May 11, 2025 -

Rory Mc Ilroys 4 Year Old Daughter Sinks Putt At Augusta Watch The Adorable Moment

May 11, 2025

Rory Mc Ilroys 4 Year Old Daughter Sinks Putt At Augusta Watch The Adorable Moment

May 11, 2025