How Electric Motor Innovation Can Counter China's Manufacturing Power

Table of Contents

Boosting Efficiency and Reducing Costs through Technological Advancements

China's manufacturing prowess is partly due to economies of scale in producing standard electric motors. To compete, we must focus on superior technology leading to greater efficiency and lower costs.

Advanced Materials

The materials used in electric motor construction significantly impact performance and cost. Current reliance on rare-earth magnets, largely sourced from China, creates a vulnerability. Innovation in this area is crucial.

- Lightweight, High-Strength Materials: Utilizing carbon fiber composites and advanced alloys reduces motor weight, improving efficiency and potentially lowering transportation costs.

- Rare-Earth-Free Magnets: Developing and implementing effective alternatives to rare-earth magnets mitigates supply chain risks associated with China's dominance in rare earth mineral processing. This is a critical aspect of electric motor innovation for national security and economic independence.

- Improved Energy Density: Lighter, stronger materials translate directly into higher energy density, meaning more power output from a smaller, lighter motor.

- Reduced Manufacturing Costs: Optimized material selection and processing can lead to significant cost reductions in electric motor production.

- Enhanced Durability: Superior materials contribute to longer motor lifespan, reducing replacement costs and minimizing downtime.

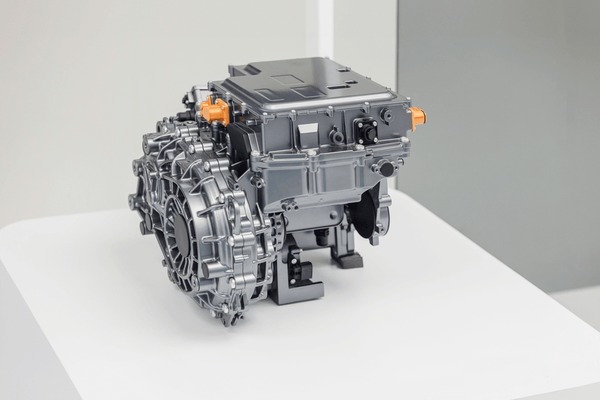

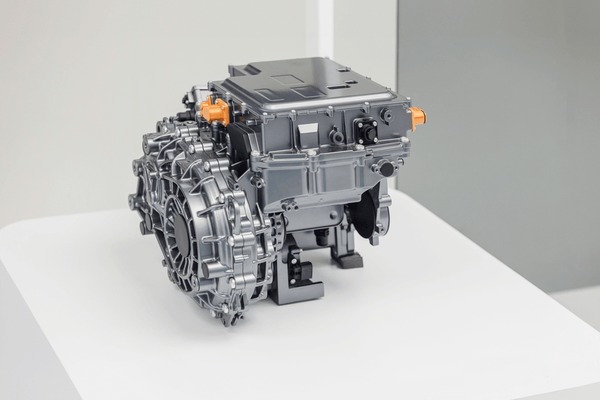

Optimized Motor Designs

Next-generation motor designs offer significant advantages over traditional configurations.

- Axial Flux Motors and Switched Reluctance Motors: These designs offer higher torque density and improved efficiency compared to traditional radial flux motors. They also present opportunities for miniaturization, making them ideal for various applications.

- Advanced Simulation and Modeling: Sophisticated computer-aided design (CAD) and finite element analysis (FEA) software enable precise motor design optimization, maximizing efficiency and minimizing energy losses. This reduces reliance on costly and time-consuming prototyping.

- Higher Power Output: Optimized designs deliver higher power output for a given size and weight, crucial for electric vehicles and industrial applications.

- Reduced Size and Weight: More compact and lighter motors improve vehicle performance, reduce energy consumption, and open new design possibilities.

- Increased Efficiency: Optimized designs minimize energy losses, resulting in significant improvements in overall efficiency.

Intelligent Control Systems

Integrating advanced control systems enhances motor performance and efficiency.

- Artificial Intelligence (AI) and Machine Learning (ML): AI and ML algorithms enable real-time motor control optimization, adapting to changing conditions for maximum efficiency.

- Predictive Maintenance: Data-driven predictive maintenance using AI reduces downtime by anticipating potential failures and scheduling maintenance proactively. This minimizes costly repairs and disruptions.

- Enhanced Precision: Intelligent control systems enable precise motor control, improving accuracy and responsiveness in various applications.

- Reduced Energy Consumption: Real-time optimization minimizes energy waste, leading to significant energy savings over the motor's lifespan.

- Improved Reliability: Predictive maintenance and intelligent control contribute to increased motor reliability and extended lifespan.

Developing Sustainable and Environmentally Friendly Electric Motor Manufacturing Processes

Sustainable manufacturing is key to long-term competitiveness.

Green Manufacturing Techniques

Minimizing environmental impact is crucial for responsible manufacturing.

- Sustainable Manufacturing Practices: Adopting lean manufacturing principles minimizes waste generation and resource consumption throughout the production process.

- Recycled Materials: Increased use of recycled materials reduces reliance on virgin resources and lowers the environmental footprint.

- Renewable Energy Sources: Powering manufacturing facilities with renewable energy reduces greenhouse gas emissions and promotes environmental responsibility.

- Reduced Carbon Footprint: Sustainable manufacturing practices significantly reduce the overall carbon footprint of electric motor production.

- Lower Manufacturing Costs: Efficient resource utilization and waste reduction can lead to cost savings in the manufacturing process.

- Improved Brand Image: Commitment to sustainability enhances brand reputation and attracts environmentally conscious consumers.

Circular Economy Models

Designing for end-of-life considerations promotes resource efficiency.

- Design for Disassembly: Designing motors for easy disassembly allows for efficient component reuse and recycling at end-of-life.

- Component Reuse and Recycling: Facilitating the recovery and reuse of valuable materials reduces waste and minimizes environmental impact.

- Collaborative Supply Chain Efforts: Collaboration across the supply chain promotes the adoption of sustainable practices and facilitates material recovery.

- Reduced Environmental Impact: Circular economy models significantly reduce the overall environmental impact of electric motor production and disposal.

- Resource Conservation: Efficient resource utilization and material recovery conserve valuable resources.

- Cost Savings through Material Recovery: Recycling valuable materials can generate cost savings and reduce reliance on new materials.

Strengthening Domestic Supply Chains and Fostering Innovation Ecosystems

A robust domestic ecosystem is critical for sustained competitiveness.

Government Support and Incentives

Government policies play a significant role in fostering innovation.

- Research and Development (R&D) Funding: Government investment in R&D is crucial for driving technological advancements in electric motor technology.

- Tax Incentives and Grants: Financial incentives encourage companies to invest in research, development, and domestic manufacturing.

- Protectionist Trade Policies (Used Cautiously): Strategic trade policies can be employed to protect domestic industries during critical development phases, but must be implemented carefully to avoid negative repercussions.

- Increased Investment in R&D: Government funding fuels innovation and accelerates the development of new technologies.

- Job Creation: Investment in the electric motor sector stimulates economic growth and creates high-skilled jobs.

- Strengthened National Competitiveness: A strong domestic industry enhances national competitiveness in the global market.

Collaboration and Partnerships

Collaboration accelerates innovation and reduces development costs.

- University-Industry Partnerships: Collaboration between universities and industry fosters knowledge transfer and accelerates the development of new technologies.

- Industry Consortia: Sharing knowledge and resources through industry consortia reduces development costs and speeds up innovation.

- Accelerated Innovation: Collaborative efforts speed up the development and deployment of new technologies.

- Reduced Development Costs: Sharing resources and expertise reduces the overall cost of research and development.

- Improved Technology Transfer: Collaboration facilitates the efficient transfer of technology between research institutions and industry.

Conclusion

China's dominance in electric motor manufacturing is a considerable challenge, but it is not insurmountable. By focusing on electric motor innovation – encompassing advancements in materials, design, manufacturing processes, and supportive policy environments – countries can effectively counter this dominance. Investing in research and development, promoting sustainable practices, and strengthening domestic supply chains are crucial steps. The future of electric motor technology relies on embracing innovation to create a more resilient and competitive global landscape. Let's leverage electric motor innovation to build a more balanced and sustainable future. Embrace electric motor innovation – it's the key to a more competitive tomorrow.

Featured Posts

-

Your Guide To The Ufc May 2025 Fight Card Ufc 315 And More

May 04, 2025

Your Guide To The Ufc May 2025 Fight Card Ufc 315 And More

May 04, 2025 -

Morning Coffee Oilers Chances Of Victory Against Montreal

May 04, 2025

Morning Coffee Oilers Chances Of Victory Against Montreal

May 04, 2025 -

L Impact De Westbrook Atout Majeur Ou Simple Statistique Denver Fait Le Point

May 04, 2025

L Impact De Westbrook Atout Majeur Ou Simple Statistique Denver Fait Le Point

May 04, 2025 -

Jean Silvas Upset Win Securing A Ufc Contract

May 04, 2025

Jean Silvas Upset Win Securing A Ufc Contract

May 04, 2025 -

Boosting Scotlands Coastline The Role Of Seagrass Planting Bids

May 04, 2025

Boosting Scotlands Coastline The Role Of Seagrass Planting Bids

May 04, 2025