Navigating The Complexities Of All-American Production

Table of Contents

Sourcing Domestically: The Challenges of All-American Raw Materials

Sourcing all materials domestically presents significant hurdles for companies aiming for all-American production. The readily available global supply chain offers a stark contrast to the complexities of domestic sourcing.

Limited Availability and Higher Costs

Finding all necessary components domestically is often difficult, leading to increased costs compared to global sourcing. This is a major factor affecting the viability of all-American manufacturing for many businesses.

- Increased transportation costs: Shipping materials across vast distances within the US can be significantly more expensive than importing from closer international locations.

- Potential for supply chain bottlenecks: Relying on a smaller pool of domestic suppliers increases vulnerability to disruptions. A single supplier issue can halt entire production lines.

- Higher labor costs for raw material extraction: The cost of labor in the US is generally higher than in many other countries, directly impacting the price of domestically sourced raw materials.

The impact of tariffs and trade restrictions further complicates domestic sourcing. These policies can increase the cost of imported materials, making domestic options seemingly more competitive, but simultaneously limiting the availability of certain specialized components.

Quality Control and Consistency

Maintaining consistent quality when relying on domestic suppliers requires a robust strategy. Unlike established global supply chains with well-vetted partners, domestic sourcing necessitates a more active approach to quality management.

- Vetting potential suppliers: Thorough due diligence is crucial to ensure suppliers meet stringent quality standards and production capacity.

- Implementing robust quality assurance procedures: Regular inspections, testing, and audits are vital to maintain consistent quality throughout the supply chain.

- Building strong supplier relationships: Collaborative partnerships with domestic suppliers foster open communication, facilitate problem-solving, and enhance overall quality control.

Strategies for mitigating risks associated with a smaller pool of domestic suppliers include diversifying sourcing where possible, establishing buffer stockpiles of critical materials, and developing flexible production plans that can adapt to supply chain fluctuations.

All-American Labor: Navigating Wages, Skills, and Regulations

Labor costs and the availability of skilled workers are significant considerations for all-American production.

Higher Labor Costs and the Skilled Labor Shortage

Higher wages in the US, while beneficial for workers, directly impact production costs. Simultaneously, a shortage of skilled labor in certain sectors creates additional challenges.

- Investing in employee training and development: Upskilling and reskilling initiatives are crucial to bridge the skills gap and create a more productive workforce.

- Exploring automation to mitigate labor shortages: Automation can help alleviate labor shortages and reduce reliance on specific skills, though it involves substantial upfront investment.

- Offering competitive compensation and benefits packages: Attracting and retaining skilled workers necessitates competitive salaries, benefits, and a positive work environment.

The decision between investing in a highly skilled workforce versus automation requires careful analysis, balancing the long-term benefits of a skilled workforce with the immediate cost savings and efficiency gains offered by automation.

Compliance with US Labor Laws and Regulations

Adherence to stringent US labor laws and regulations is paramount for all-American manufacturers. Non-compliance can result in significant penalties.

- Ensuring fair wages and working conditions: Companies must comply with minimum wage laws, overtime regulations, and provide safe working environments.

- Complying with safety regulations: Meeting OSHA standards and other safety protocols is crucial to prevent workplace accidents and injuries.

- Navigating complex employment laws: Understanding and adhering to various employment laws, including those related to hiring, firing, and employee benefits, is essential.

Failure to comply with these regulations can lead to substantial fines, legal battles, and reputational damage, ultimately undermining the benefits of all-American production.

Infrastructure and Logistics for All-American Manufacturing

Efficient transportation and a robust domestic infrastructure are vital for the success of all-American production.

Transportation and Distribution Challenges

Transporting raw materials and finished goods across the vast distances of the US poses unique challenges.

- Utilizing efficient transportation networks: Leveraging rail, road, and other transportation modes strategically is key to minimizing costs and maximizing efficiency.

- Optimizing logistics routes: Careful planning and route optimization can significantly reduce transportation times and costs.

- Managing inventory effectively: Efficient inventory management minimizes storage costs and ensures timely delivery of materials and finished goods.

The cost-effectiveness of different transportation methods varies depending on factors such as distance, volume, and the type of goods being transported. Careful analysis is necessary to determine the most efficient approach.

Investing in Domestic Infrastructure

Investing in and advocating for improvements in US infrastructure is critical for long-term success in all-American manufacturing.

- Advocating for infrastructure improvements: Supporting policies that promote investment in roads, railways, and ports is essential for smoother logistics.

- Partnering with local communities: Collaboration with local communities can create a supportive environment for manufacturing businesses.

- Leveraging government incentives: Many government programs offer incentives to businesses investing in domestic production and infrastructure.

Investing in infrastructure yields long-term benefits, including reduced transportation costs, improved efficiency, and enhanced competitiveness for American manufacturers.

Conclusion

Successfully navigating the complexities of all-American production requires a strategic approach that carefully considers sourcing, labor, and logistics. While challenges exist—including higher costs and potential supply chain limitations—the benefits of supporting domestic jobs, fostering economic growth, and controlling quality are significant. By carefully planning and investing in the right resources, businesses can successfully achieve their all-American production goals. Embrace the challenges and reap the rewards of truly All-American Production. Contact us today to learn more about strategies for optimizing your domestic manufacturing process and achieving your all-American manufacturing dreams.

Featured Posts

-

You Tubes Growing Popularity Among Older Viewers A Resurgence Of Classic Content

Apr 29, 2025

You Tubes Growing Popularity Among Older Viewers A Resurgence Of Classic Content

Apr 29, 2025 -

Mapping The Countrys Emerging Business Hotspots

Apr 29, 2025

Mapping The Countrys Emerging Business Hotspots

Apr 29, 2025 -

Understanding Russias Military Actions And Their Impact On Europe

Apr 29, 2025

Understanding Russias Military Actions And Their Impact On Europe

Apr 29, 2025 -

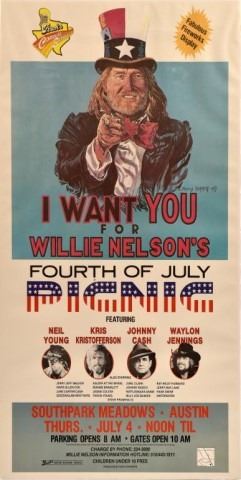

The Willie Nelson 4th Of July Picnic Back In Texas

Apr 29, 2025

The Willie Nelson 4th Of July Picnic Back In Texas

Apr 29, 2025 -

D C Black Hawk Crash Investigation Reveals Pilots Pre Crash Decisions

Apr 29, 2025

D C Black Hawk Crash Investigation Reveals Pilots Pre Crash Decisions

Apr 29, 2025