Obstacles To Producing All-American Products

Table of Contents

High Production Costs in the USA

One of the most significant barriers to producing All-American products is the substantially higher cost of production compared to many other countries. This cost differential stems primarily from two major factors: labor costs and raw material costs.

Labor Costs

American workers command significantly higher wages than their counterparts in many developing nations. This disparity is influenced by several factors:

- Higher minimum wages: The US minimum wage is considerably higher than in many other countries, directly increasing labor costs.

- Employee benefits: American companies typically provide comprehensive employee benefits packages, including healthcare and retirement plans, adding considerably to labor expenses.

- Unionization: The prevalence of labor unions in certain sectors further elevates labor costs through negotiated wages and benefits.

These higher labor costs directly impact the pricing and profitability of All-American products, making them less competitive against cheaper imports. While automation offers a potential solution, the significant upfront investment and limitations in fully automating all processes present substantial hurdles for many businesses.

Raw Material Costs

Sourcing raw materials domestically presents another significant cost challenge. Several factors contribute to this:

- Dependence on imported materials: The US remains reliant on imported raw materials for many manufacturing processes, exposing businesses to fluctuating global commodity prices and transportation costs.

- Fluctuating commodity prices: The price volatility of raw materials, particularly energy and certain metals, significantly impacts production costs and makes long-term planning difficult.

- Transportation costs: Moving raw materials across the vast distances within the US can be expensive, adding to the overall cost of production.

- Lack of domestic supply: For some specialized materials, there may be a complete lack of domestic supply, forcing manufacturers to rely on imports.

Businesses striving to create completely All-American products often find themselves navigating a complex web of sourcing challenges, potentially opting for smaller, regional suppliers to reduce transportation costs and support local economies. This strategy, however, may not always be feasible depending on the scale of production and the availability of suitable domestic suppliers.

Intense Import Competition

All-American product manufacturers face intense competition from cheaper imports, creating a challenging market environment.

Lower Prices from Overseas

The lower production costs in many other countries translate directly into lower prices for imported goods. This price advantage is driven by:

- Lower labor costs: As discussed above, labor costs significantly contribute to the price competitiveness of imports.

- Government subsidies: Foreign governments often provide subsidies to their manufacturers, further bolstering their competitive edge.

- Economies of scale: Foreign manufacturers often benefit from economies of scale, resulting in lower unit production costs.

This price differential makes it extremely difficult for All-American products to compete on price alone, demanding a focus on differentiating strategies.

Trade Policies and Tariffs

International trade policies and tariffs play a significant role in shaping the competitiveness of domestic manufacturing. While tariffs can protect domestic industries by making imports more expensive, they can also increase the cost of raw materials if those materials are imported.

- Impact of tariffs on raw material costs: Tariffs on imported raw materials increase production costs for All-American manufacturers.

- Potential retaliatory tariffs: The imposition of tariffs can lead to retaliatory tariffs from other countries, further complicating the situation.

- Navigating complex trade regulations: Understanding and navigating complex trade regulations is a significant burden for businesses trying to produce All-American products.

Careful consideration of trade policy is essential when promoting domestic production. The impact of tariffs can be complex and often unpredictable, requiring a nuanced approach.

Supply Chain Challenges

Further complicating the production of All-American products are significant challenges related to the US supply chain.

Infrastructure Limitations

The US infrastructure, encompassing transportation and logistics networks, presents limitations impacting efficient domestic production. These limitations include:

- Port congestion: Congestion at major US ports causes delays and increased shipping costs.

- Aging infrastructure: The aging state of roads, railways, and other infrastructure adds to transportation costs and inefficiencies.

- Lack of sufficient transportation networks: In some regions, a lack of adequate transportation networks hinders the efficient movement of goods.

These infrastructure shortcomings translate into increased costs and delays, making it more difficult for All-American manufacturers to compete on timeliness and price.

Skilled Labor Shortages

A shortage of skilled workers in certain manufacturing sectors further hampers the production of All-American products. This shortage is driven by:

- Lack of vocational training: Insufficient investment in vocational training programs has resulted in a skills gap in many areas of manufacturing.

- Aging workforce: Many skilled manufacturing workers are nearing retirement, creating a looming skills shortage.

- Competition for skilled labor: Other sectors compete for the same pool of skilled labor, making it difficult for manufacturers to attract and retain qualified employees.

Investing in robust vocational training programs and fostering attractive career paths in manufacturing is critical to addressing these skill shortages and ensuring the future of All-American production.

Conclusion

Producing All-American products presents significant challenges, primarily high production costs, intense import competition, and substantial supply chain hurdles. The higher cost of labor and raw materials in the US, coupled with the competitive pressure from cheaper imports and supply chain bottlenecks, creates a complex environment for domestic manufacturers. However, the growing consumer demand for domestically-produced goods highlights the importance of addressing these challenges. We need to support initiatives aimed at boosting domestic manufacturing, including investment in infrastructure, vocational training, and policies that foster a level playing field for All-American producers. Learn more about reshoring initiatives and the economic impact of "Made in the USA" goods. Support businesses committed to producing All-American products and advocate for policies that promote domestic manufacturing. Choose All-American products whenever possible – it's an investment in our nation's economic future.

Featured Posts

-

How The Uk Courts Definition Of Woman Could Reshape Sex Based Rights For Transgender People

Apr 29, 2025

How The Uk Courts Definition Of Woman Could Reshape Sex Based Rights For Transgender People

Apr 29, 2025 -

M Ivaskeviciaus Isvarymo Analize 11 Aspektu Kuriuos Svarbu Zinoti

Apr 29, 2025

M Ivaskeviciaus Isvarymo Analize 11 Aspektu Kuriuos Svarbu Zinoti

Apr 29, 2025 -

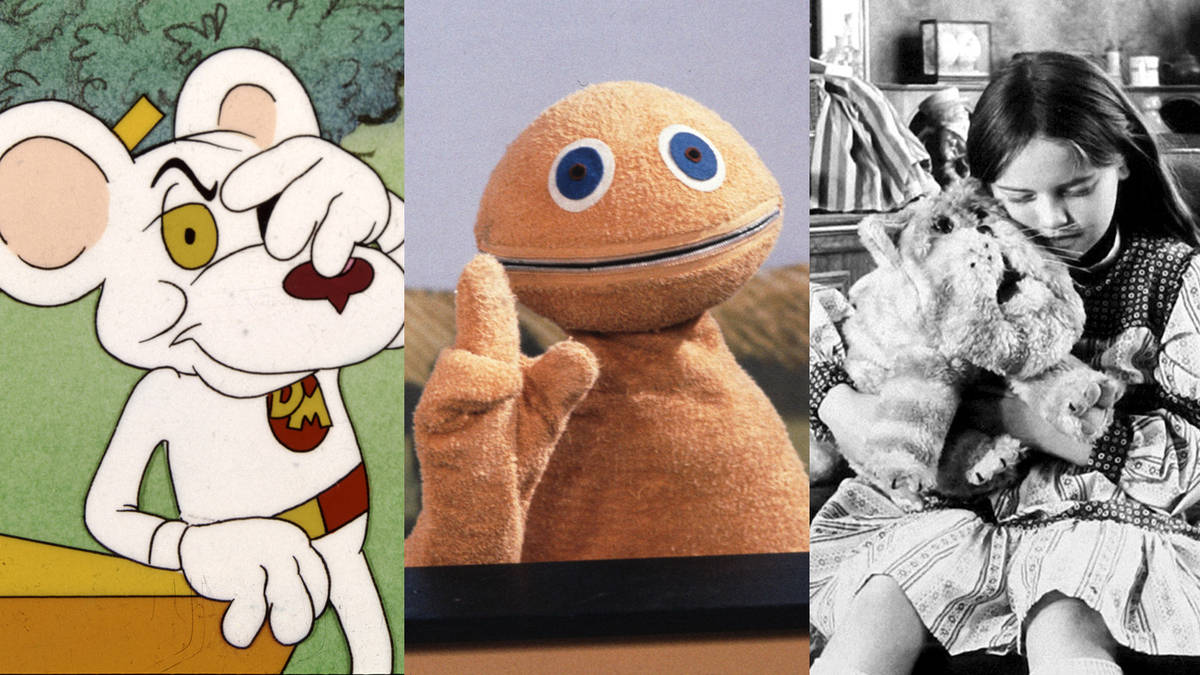

You Tube A New Home For Classic Tv Shows And Beloved Programs For Mature Audiences

Apr 29, 2025

You Tube A New Home For Classic Tv Shows And Beloved Programs For Mature Audiences

Apr 29, 2025 -

Mark Carneys Chances Diminish As Canadian Election Heats Up

Apr 29, 2025

Mark Carneys Chances Diminish As Canadian Election Heats Up

Apr 29, 2025 -

Vancouver Festival Tragedy Car Rams Crowd Leaving Many Injured

Apr 29, 2025

Vancouver Festival Tragedy Car Rams Crowd Leaving Many Injured

Apr 29, 2025