Overcoming Hurdles In Automated Visual Inspection Of Lyophilized Vials

Table of Contents

Challenges in Automated Visual Inspection of Lyophilized Vials

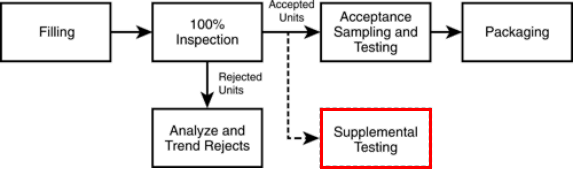

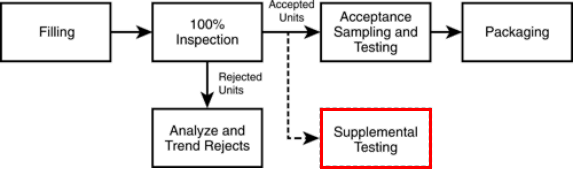

Automated visual inspection systems offer a significant advancement over manual methods, but implementing them for lyophilized vials presents unique challenges. These hurdles stem from the inherent variability of the lyophilization process and the subtleties of the defects needing detection.

Variations in Lyophilization Processes

Different lyophilization cycles, even when targeting the same product, can result in varied cake appearances. This makes consistent automated detection incredibly difficult. Slight variations in parameters can lead to significant differences in the final product.

- Variations in cake density: Density variations can affect light reflection and scattering, impacting image analysis.

- Variations in color: Subtle color changes can indicate inconsistencies in the lyophilization process or the presence of defects.

- Variations in surface texture: Surface irregularities can be challenging to detect consistently using automated systems.

- Impact of different vial types and sizes: Different vial materials and geometries can influence light scattering and shadowing, requiring adjustments to the inspection system.

- Differentiating acceptable variations from defects: Distinguishing between natural variations within acceptable limits and actual defects requires sophisticated algorithms and careful calibration.

Difficulties in Defect Detection

Identifying subtle defects in lyophilized vials presents a significant challenge for automated systems. These defects can include:

- Cracks: Tiny cracks in the lyophilized cake can be difficult to detect, especially when partially obscured.

- Particulate matter: Small particles within the vial can indicate contamination and are crucial to identify.

- Discoloration: Slight changes in color can signal degradation or contamination.

These challenges highlight the limitations of current imaging technology:

- Sensitivity limitations: Existing systems may lack the sensitivity to detect very small or subtle defects.

- Need for advanced algorithms: Sophisticated image processing algorithms and machine learning are crucial for accurate defect detection.

- False positive and false negative rates: Balancing the minimization of both false positives (rejecting good vials) and false negatives (accepting defective vials) is crucial for effective automated inspection.

Lighting and Image Acquisition Challenges

Achieving consistent and optimal lighting is critical for accurate defect detection. Poor lighting can mask or exaggerate defects.

- Impact of shadowing and reflections: Shadows and reflections can obscure defects or create false positives. Careful control of lighting angles and intensities is necessary.

- Need for specialized lighting systems: Specialized lighting systems, such as coaxial or ring lights, are often required to minimize shadowing and reflections.

- Calibration and maintenance of imaging systems: Regular calibration and maintenance of the imaging system are essential to maintain consistent performance and accuracy.

Strategies for Overcoming these Hurdles

Several strategies can mitigate the challenges outlined above and enable successful implementation of automated visual inspection systems for lyophilized vials.

Advanced Imaging Techniques

Employing cutting-edge imaging technologies significantly enhances defect detection capabilities.

- High-resolution imaging: Higher resolution provides greater detail, improving the detection of subtle defects.

- Multispectral imaging: Capturing images at multiple wavelengths can highlight defects that are invisible to the naked eye or in standard visible light.

- 3D imaging for improved depth perception: 3D imaging provides a more complete view of the vial contents, improving the detection of cracks and internal defects.

- Integration of hyperspectral imaging: Hyperspectral imaging provides detailed spectral information about the lyophilized cake, potentially enabling the detection of subtle chemical or physical changes indicative of defects.

AI-Powered Image Analysis

Artificial intelligence (AI) and machine learning (ML) are essential for automated defect classification and analysis.

- Training AI models with large datasets of images: A large, representative dataset of images, including both defective and non-defective vials, is crucial for training accurate AI models.

- Continual learning and model refinement: AI models require continuous training and refinement to adapt to variations in the lyophilization process and improve accuracy over time.

- Integration of deep learning techniques: Deep learning techniques can significantly improve the accuracy of defect detection and classification.

Improved Process Control and Standardization

Minimizing variations in the lyophilization process directly simplifies automated inspection.

- Strict adherence to standardized procedures: Following strict, well-documented procedures reduces variability in the final product.

- Real-time process monitoring: Real-time monitoring of critical parameters during the lyophilization process allows for early detection and correction of any deviations.

- Data analytics for process optimization: Analyzing data from the lyophilization process can identify and address sources of variability.

- Implementing quality by design (QbD) principles: Implementing QbD principles proactively reduces variability and enhances process understanding.

Benefits of Successful Automated Visual Inspection

Successful implementation of automated visual inspection systems offers numerous benefits:

Increased Efficiency and Throughput

Automated systems drastically increase inspection speed compared to manual methods.

- Reduced labor costs: Automating the inspection process reduces the need for manual labor.

- Increased production capacity: Higher inspection speeds enable increased production capacity.

- Faster time-to-market: Faster inspection leads to faster product release and time-to-market.

Improved Accuracy and Reduced Human Error

Automated systems offer consistent and objective inspection results.

- Minimized false positives and negatives: Automated systems reduce both false positives (rejecting good vials) and false negatives (accepting defective vials).

- Higher product quality and reliability: Consistent and accurate inspection leads to higher product quality and reliability.

- Enhanced patient safety: Improved quality control contributes to enhanced patient safety.

Better Data Management and Traceability

Automated systems generate detailed inspection reports.

- Improved compliance with regulatory requirements: Detailed reports facilitate compliance with regulatory requirements.

- Facilitates continuous improvement initiatives: Data from automated inspections can be used to identify areas for process improvement.

- Supports efficient investigation of defects: Detailed records support efficient investigations into the root causes of defects.

Conclusion

Implementing automated visual inspection of lyophilized vials presents significant challenges, but the benefits in terms of efficiency, accuracy, and data management are substantial. By employing advanced imaging techniques, AI-powered image analysis, and improved process controls, the pharmaceutical industry can overcome these hurdles and ensure the delivery of high-quality products. Investing in robust and reliable automated visual inspection systems is key to achieving superior quality control and meeting the stringent demands of the modern pharmaceutical market. Explore the latest advancements in automated visual inspection technology to improve your lyophilized vial inspection processes today!

Featured Posts

-

Premiere Parisienne D Eric Antoine Presence Remarquee D Une Ancienne Miss Meteo

May 11, 2025

Premiere Parisienne D Eric Antoine Presence Remarquee D Une Ancienne Miss Meteo

May 11, 2025 -

Nine Faces One Destiny The Vaticans Search For Pope Francis Successor

May 11, 2025

Nine Faces One Destiny The Vaticans Search For Pope Francis Successor

May 11, 2025 -

Blue Origin Postpones Launch Investigation Into Subsystem Issue

May 11, 2025

Blue Origin Postpones Launch Investigation Into Subsystem Issue

May 11, 2025 -

The Ultimate Guide To The Mansions Showcased On Mtv Cribs

May 11, 2025

The Ultimate Guide To The Mansions Showcased On Mtv Cribs

May 11, 2025 -

Ufc 315 Watch Belal Muhammad And Jack Della Maddalenas Tense Faceoff

May 11, 2025

Ufc 315 Watch Belal Muhammad And Jack Della Maddalenas Tense Faceoff

May 11, 2025