Reducing Reliance On China: The Promise Of Advanced Electric Motors

Table of Contents

The Current State of Electric Motor Manufacturing and China's Dominance

China's Control over the Supply Chain

China plays a dominant role in the global electric motor supply chain, particularly concerning the production of rare earth elements (REEs) like neodymium, a critical component in high-performance electric motors. This dominance stems from:

- High concentration of rare earth mining and processing: China controls a significant portion of the world's rare earth mining and processing capacity, giving them a considerable advantage in the production of neodymium magnets.

- Dominance in magnet manufacturing: This control extends to the manufacturing of neodymium magnets themselves, further solidifying China's position in the electric motor supply chain. Many manufacturers rely on Chinese-produced magnets for their electric motor assemblies.

- Cost advantages leading to market share dominance: China's economies of scale and lower labor costs have enabled them to offer highly competitive pricing, securing a substantial market share in the global electric motor industry.

Geopolitical and Economic Vulnerabilities

Relying heavily on a single nation for such a critical technology as electric motors creates significant vulnerabilities:

- Trade disputes: Escalating trade tensions could disrupt the supply of electric motors and their components, impacting various industries reliant on this technology.

- Supply chain disruptions: Geopolitical instability, natural disasters, or pandemics within China could severely disrupt the global supply of electric motors, leading to production delays and shortages.

- Potential for price manipulation: China's dominance allows for the potential manipulation of prices, impacting the profitability and competitiveness of industries using electric motors.

- National security concerns: Over-dependence on a single nation for a crucial technology like electric motors poses a significant national security risk, especially for military and critical infrastructure applications.

Strategies for Reducing Reliance on China for Electric Motors

Investing in Domestic Manufacturing and Research & Development

To reduce reliance on China, substantial investment in domestic electric motor production is vital:

- Incentives for domestic manufacturing: Government policies offering tax breaks, subsidies, and other incentives can encourage companies to establish or expand electric motor manufacturing facilities within their own countries.

- Funding for research and development in advanced motor technologies: Investing in R&D is crucial for developing innovative motor designs and materials that reduce reliance on rare earth elements.

- Development of a skilled labor force: Training and education programs are needed to ensure a sufficient workforce with the expertise required for advanced electric motor manufacturing.

Diversifying the Supply Chain

Diversifying the sources of rare earth elements and other critical materials is crucial:

- Exploring mines in other countries: Countries like Australia, the USA, and Canada possess significant rare earth reserves and are actively developing their mining and processing capacities.

- Recycling and reuse of rare earth magnets: Developing efficient recycling processes for neodymium magnets can significantly reduce reliance on new mining operations.

- Development of alternative motor designs reducing rare earth dependence: Research into alternative motor designs that use fewer or no rare earth elements is essential for long-term independence. This includes exploring motors using ferrite magnets or other materials.

Fostering Technological Innovation

Technological advancements are key to breaking China's hold on the electric motor market:

- Research into new motor designs: Developing more efficient and powerful motor designs can reduce the need for large quantities of rare earth elements.

- Advanced materials: Exploring alternative materials with similar magnetic properties to neodymium but with less reliance on China's supply is critical.

- Improved manufacturing processes: Optimizing manufacturing processes can enhance efficiency and reduce costs, making domestic production more competitive.

- Development of next-generation electric motors: Investing in research and development for next-generation electric motors, such as those incorporating advanced materials and designs, will secure long-term independence.

The Benefits of Reducing China Dependence on Electric Motors

Enhanced National Security

Reducing reliance on China significantly enhances national security:

- Reduced vulnerability to geopolitical pressures: A diversified and robust domestic supply chain ensures continued access to critical technologies, regardless of geopolitical events.

- Greater control over pricing: Domestic production reduces vulnerability to price manipulation by foreign suppliers.

- Improved national security: Secure domestic supply chains are essential for critical infrastructure and defense applications.

Economic Growth and Job Creation

Reshoring electric motor manufacturing stimulates economic growth:

- Creation of high-skilled jobs: The electric motor industry creates high-paying jobs in manufacturing, engineering, and research.

- Stimulation of economic activity in manufacturing regions: Domestic production revitalizes manufacturing regions and strengthens local economies.

- Increased competitiveness: A strong domestic electric motor industry enhances the competitiveness of various sectors relying on this technology.

Environmental Sustainability

Sustainable manufacturing practices are integral to a responsible transition:

- Reduced carbon footprint from transportation: Domestic production reduces the environmental impact of long-distance transportation of components and finished products.

- Responsible sourcing of materials: Implementing responsible sourcing practices for raw materials minimizes the environmental impact of mining and processing.

- Implementation of green manufacturing processes: Adopting eco-friendly manufacturing techniques throughout the production process reduces the overall environmental footprint.

Conclusion

Reducing reliance on China for advanced electric motors is not merely a strategic imperative, but a crucial step towards building a more resilient and sustainable global economy. By investing in domestic manufacturing, diversifying supply chains, and driving technological innovation, we can mitigate geopolitical risks, boost economic growth, and ensure a secure future for the electric motor industry. The transition away from over-reliance on China requires a concerted effort from governments, businesses, and research institutions. Let's seize this opportunity to build a more robust and independent future for advanced electric motor technology. Embrace the promise of advanced electric motors – invest in a resilient future, independent of China.

Featured Posts

-

Stones Upcoming Announcement Virginia Derby At Colonial Downs

May 04, 2025

Stones Upcoming Announcement Virginia Derby At Colonial Downs

May 04, 2025 -

The Count Of Monte Cristo A Review Of Alexandre Dumass Enduring Tale

May 04, 2025

The Count Of Monte Cristo A Review Of Alexandre Dumass Enduring Tale

May 04, 2025 -

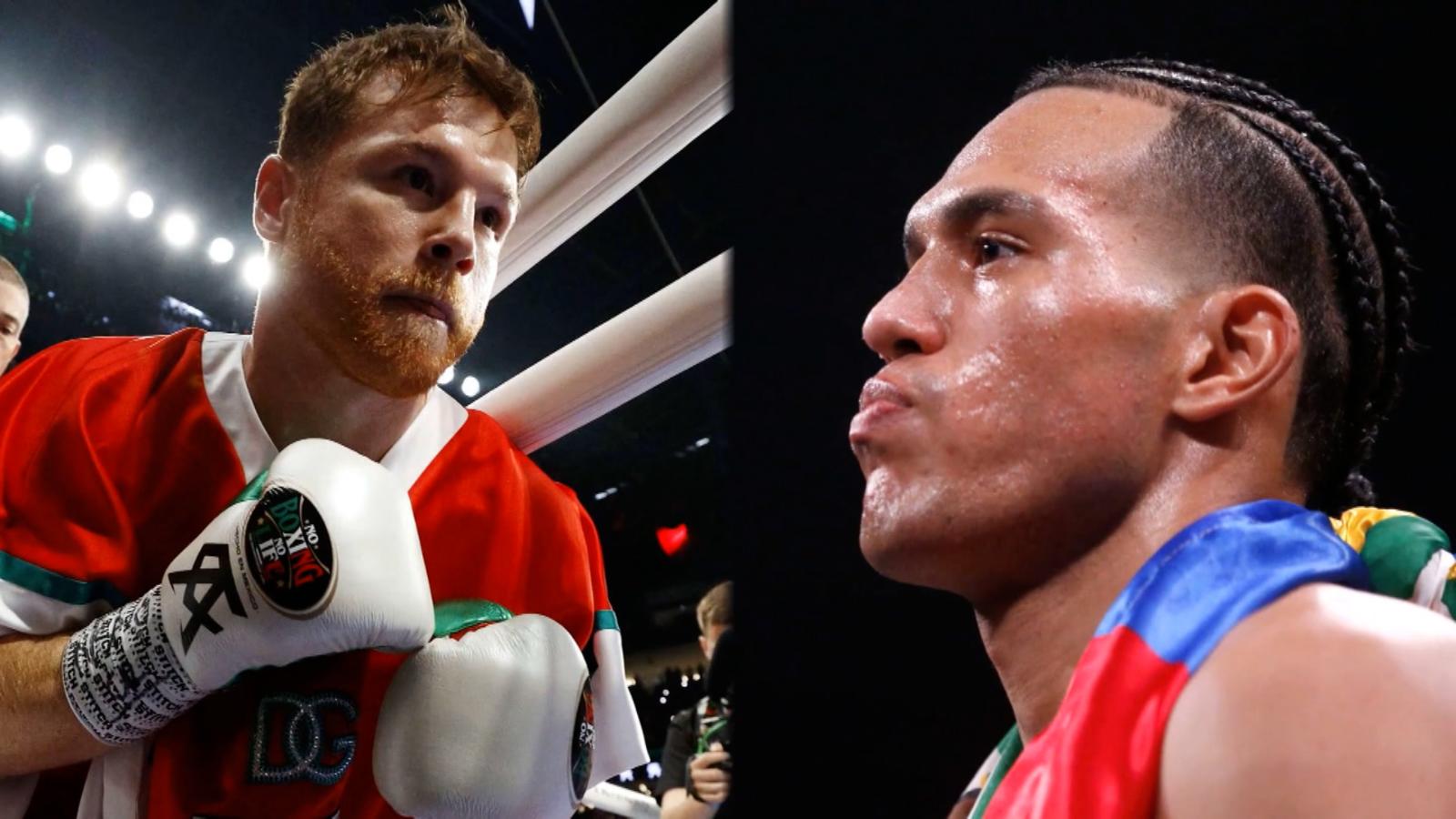

Canelo Alvarezs Criticism Of David Benavidez The Full Story

May 04, 2025

Canelo Alvarezs Criticism Of David Benavidez The Full Story

May 04, 2025 -

Indy Cars New Tv Home A Look At Foxs Inaugural Season

May 04, 2025

Indy Cars New Tv Home A Look At Foxs Inaugural Season

May 04, 2025 -

Alvarez Vs Plant Canelos Full Attention Before Crawford Consideration

May 04, 2025

Alvarez Vs Plant Canelos Full Attention Before Crawford Consideration

May 04, 2025