Reviving American Factories: Assessing The Challenges And Opportunities

Table of Contents

The Challenges Facing American Manufacturing

The path to revitalizing American factories is paved with significant hurdles. These challenges are interconnected and demand multifaceted solutions.

H3: Automation and Technological Disruption

Automation and advanced technologies, while offering increased efficiency, have significantly impacted American factory jobs. The rise of robotics, AI-powered systems, and sophisticated automation processes has led to job displacement in several sectors. This necessitates a proactive approach to reskilling and upskilling the workforce.

- Job displacement due to automation: Many traditional manufacturing roles are being replaced by automated systems, requiring workers to adapt to new skill sets.

- The need for workforce retraining programs: Government and private sector partnerships are crucial for providing comprehensive retraining programs focusing on advanced manufacturing technologies.

- The high cost of implementing new technologies: The initial investment required for automation and advanced technologies can be substantial, posing a barrier for smaller manufacturers. Access to affordable financing and government grants is crucial.

- Keyword variations: Factory automation, reskilling initiatives, Industry 4.0 workforce, technological advancements in manufacturing, automation and jobs.

H3: Global Competition and Trade Imbalances

Global competition, especially from countries with lower labor costs, poses a constant challenge. Trade imbalances and unfair trade practices further exacerbate this issue. American manufacturers often face difficulty competing with imports priced significantly lower due to cheaper labor and relaxed environmental regulations.

- Impact of cheaper imports: The influx of cheaper imports undermines the competitiveness of domestic manufacturers.

- Trade wars and their consequences: Trade disputes and tariffs can disrupt supply chains and increase costs for both manufacturers and consumers.

- The need for fair trade practices: A level playing field is crucial, requiring fair trade agreements that address issues like dumping and subsidies.

- Strengthening domestic supply chains: Reducing reliance on foreign suppliers and fostering domestic supply chain resilience is vital for the long-term health of American manufacturing.

- Keyword variations: Global manufacturing competition, trade policy, import/export balance, reshoring, nearshoring, fair trade, supply chain resilience.

H3: Infrastructure Deficiencies

Outdated infrastructure significantly hinders the ability of American factories to operate efficiently. Inadequate transportation networks, unreliable energy grids, and limited high-speed internet access in certain areas contribute to higher costs and reduced productivity.

- Outdated infrastructure: Many transportation networks, energy grids, and communication systems are aging and in need of significant upgrades.

- High transportation costs: Inefficient logistics and transportation networks lead to higher costs for transporting raw materials and finished goods.

- Unreliable energy grids: Power outages and unreliable energy supply can disrupt manufacturing operations and lead to significant losses.

- Lack of high-speed internet access in some areas: The digital transformation of manufacturing requires reliable high-speed internet access, which is lacking in certain regions.

- Keyword variations: Infrastructure investment, improving logistics, energy efficiency in factories, digital infrastructure for manufacturing, transportation infrastructure, energy grid modernization.

H3: Labor Shortages and Skills Gaps

A significant challenge lies in the shortage of skilled labor to fill advanced manufacturing roles. Attracting and retaining a skilled workforce is crucial for the future of American manufacturing.

- Lack of qualified workers: There is a significant mismatch between the skills possessed by the available workforce and the skills required for modern manufacturing jobs.

- Attracting younger generations to manufacturing careers: Promoting manufacturing as a high-tech, high-skilled, and well-paying career path is essential to attract younger talent.

- Improving technical education and vocational training: Investing in robust vocational training programs and technical education initiatives is key to building a skilled manufacturing workforce.

- Keyword variations: Manufacturing workforce, skilled labor shortage, vocational training programs, attracting talent to manufacturing, STEM education, workforce development.

Opportunities for Revitalizing American Factories

Despite the challenges, significant opportunities exist for the revitalization of American factories. A strategic approach leveraging these opportunities can lead to a robust and competitive manufacturing sector.

H3: Government Policies and Incentives

Targeted government policies and incentives play a vital role in supporting domestic manufacturing. Tax incentives, grants, subsidies, and investments in research and development can significantly boost the sector.

- Tax breaks for manufacturers: Tax incentives can encourage investment in new equipment, facilities, and technology.

- Investment in research and development: Government funding for research and development in advanced manufacturing technologies is crucial for fostering innovation.

- Government procurement policies favoring American-made goods: Prioritizing American-made products in government procurement can create demand and support domestic manufacturers.

- Keyword variations: Government support for manufacturing, industrial policy, tax incentives for factories, manufacturing grants, research and development funding.

H3: Focus on Innovation and Advanced Technologies

American factories have the potential to lead in advanced manufacturing technologies. Embracing innovation and investing in technologies like 3D printing, additive manufacturing, and Industry 4.0 solutions is key.

- Investing in R&D: Focusing on research and development to create cutting-edge manufacturing technologies is essential for maintaining competitiveness.

- Adopting Industry 4.0 technologies: Implementing smart factory technologies, such as automation, data analytics, and the Internet of Things (IoT), can improve efficiency and productivity.

- Fostering innovation hubs: Creating centers for collaboration and innovation can accelerate the development and adoption of new technologies.

- Attracting tech talent to manufacturing: Bridging the gap between technology and manufacturing by attracting skilled tech professionals to the sector is vital.

- Keyword variations: Advanced manufacturing technologies, Industry 4.0, innovation in manufacturing, technological leadership, smart factories, digital manufacturing.

H3: Sustainability and Green Manufacturing

The growing demand for sustainable and environmentally friendly products presents a significant opportunity. Adopting green manufacturing practices can attract environmentally conscious consumers and create new markets.

- Reducing carbon footprint: Implementing energy-efficient technologies and reducing waste can significantly minimize environmental impact.

- Implementing circular economy principles: Adopting strategies to reduce waste, reuse materials, and recycle products can improve sustainability.

- Using renewable energy sources: Transitioning to renewable energy sources can reduce reliance on fossil fuels and lower carbon emissions.

- Creating green jobs: Investing in green manufacturing creates jobs in sustainable industries and helps meet environmental goals.

- Keyword variations: Sustainable manufacturing, green technologies, eco-friendly factories, environmental responsibility in manufacturing, circular economy, green jobs.

H3: Reshoring and Nearshoring

The trend of reshoring (bringing manufacturing back to the US) and nearshoring (relocating manufacturing to nearby countries) is gaining momentum. This reduces reliance on long and complex global supply chains, improving resilience and creating jobs domestically.

- Reducing reliance on overseas production: Bringing manufacturing back to the US enhances supply chain security and reduces vulnerability to global disruptions.

- Benefits of shorter supply chains: Shorter supply chains lead to faster delivery times, reduced transportation costs, and improved responsiveness to market demand.

- Improved logistics and delivery times: Reshoring and nearshoring enable faster and more efficient delivery of goods to customers.

- Job creation in the US: Bringing manufacturing back to the US creates jobs and boosts economic growth in local communities.

- Keyword variations: Reshoring initiatives, nearshoring strategies, supply chain resilience, bringing manufacturing jobs back to America, domestic manufacturing, onshoring.

Conclusion

Reviving American factories presents both significant challenges and substantial opportunities. Addressing labor shortages through robust training programs, improving infrastructure to support modern manufacturing, embracing innovation and advanced technologies, and leveraging government support are crucial steps. The path forward requires a collaborative effort involving government, industry, and educational institutions. A focus on sustainability and reshoring will further strengthen the American manufacturing sector's competitiveness. Explore opportunities in the resurgent American manufacturing sector and learn more about how you can contribute to the revival of American factories. The future of American manufacturing depends on our collective commitment to revitalizing this vital sector of our economy.

Featured Posts

-

South China Sea Tensions Rise China Pressures Philippines On Missile Deployment

May 20, 2025

South China Sea Tensions Rise China Pressures Philippines On Missile Deployment

May 20, 2025 -

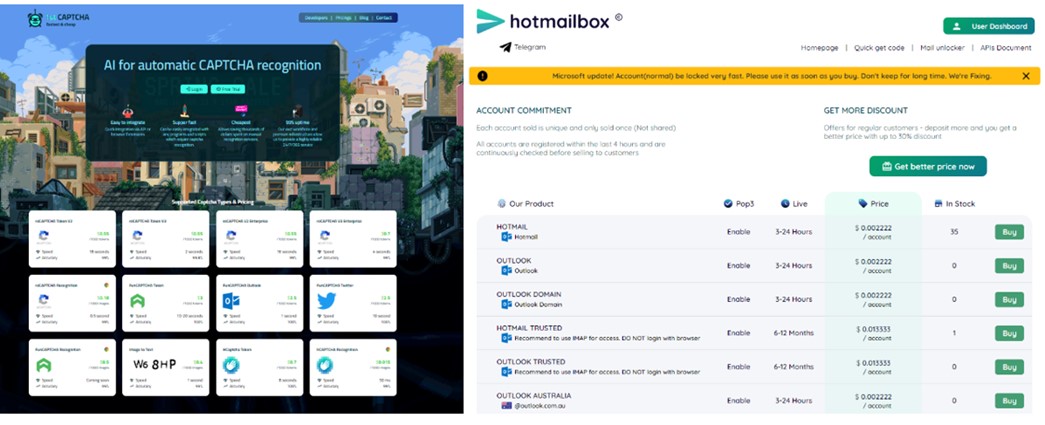

Cybercriminal Made Millions From Compromised Office365 Accounts

May 20, 2025

Cybercriminal Made Millions From Compromised Office365 Accounts

May 20, 2025 -

Conseil Municipal De Biarritz Debat Sur Les Logements Saisonniers Et Le Budget

May 20, 2025

Conseil Municipal De Biarritz Debat Sur Les Logements Saisonniers Et Le Budget

May 20, 2025 -

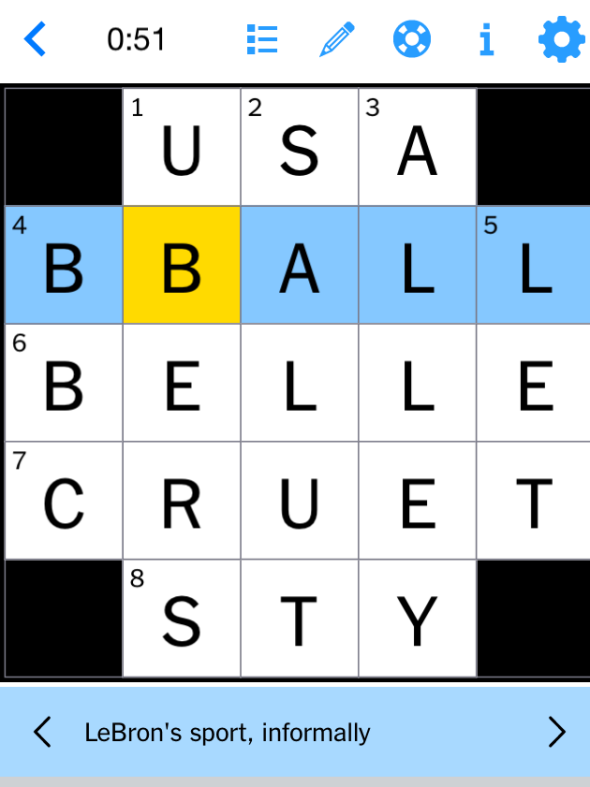

May 9 Nyt Mini Crossword Puzzle Answers

May 20, 2025

May 9 Nyt Mini Crossword Puzzle Answers

May 20, 2025 -

The World Of Agatha Christies Poirot Characters Plots And Adaptations

May 20, 2025

The World Of Agatha Christies Poirot Characters Plots And Adaptations

May 20, 2025