Right-to-Repair: How The US Army Is Modernizing Its Maintenance Practices

Table of Contents

The Challenges of Traditional Military Maintenance

Traditional military maintenance practices have presented significant hurdles to the Army's operational efficiency. These challenges stem from several key areas:

High Costs of Outsourcing

Historically, the Army has heavily relied on original equipment manufacturers (OEMs) for equipment repairs. This dependence has resulted in exorbitant costs.

- Limited repair options: Reliance on a single vendor limits choices and negotiating power.

- Lengthy repair times: OEM repair processes often involve lengthy lead times, resulting in equipment downtime.

- Dependence on single vendors: This creates a vulnerability to price gouging and supply chain disruptions.

- Lack of transparency: The lack of accessible repair information limits the Army's ability to understand and address repair costs effectively.

Logistical Bottlenecks

The traditional military supply chain presents significant logistical bottlenecks that hinder equipment availability.

- Slow turnaround times: Repair cycles are often protracted, leading to extended periods of equipment unavailability.

- Parts shortages: Obtaining replacement parts can be slow and difficult, delaying repairs.

- Difficulties in transporting equipment: Moving heavy or specialized equipment for repair can be complex and costly.

- Centralized repair facilities: This creates a single point of failure and can overwhelm the system during peak demand.

Environmental Impact

Discarding broken equipment instead of repairing it has significant environmental consequences.

- Increased e-waste: The disposal of obsolete military equipment contributes to the growing problem of electronic waste.

- Resource depletion: Manufacturing new equipment consumes significant resources and energy.

- Carbon footprint of transportation and manufacturing: Shipping equipment for repair and manufacturing new units generates substantial carbon emissions.

The Right-to-Repair Movement and its Impact on the Army

The Right-to-Repair movement, advocating for increased access to repair information and parts, is significantly impacting the Army's maintenance strategies.

Increased Access to Repair Information

Open-source repair manuals, diagnostic tools, and online communities are empowering Army mechanics.

- Faster troubleshooting: Access to comprehensive information allows for quicker diagnosis and resolution of equipment issues.

- Reduced downtime: Faster repairs translate directly into less downtime for critical equipment.

- Increased self-sufficiency of units in the field: Forward-deployed units can perform more repairs independently, reducing reliance on centralized support.

- Better training opportunities: Access to repair information enhances training opportunities for Army mechanics.

Third-Party Repair Options

Allowing qualified independent repair shops to service Army equipment introduces competition and innovation.

- Increased competition: This drives down repair costs and encourages higher quality of service.

- Lower repair costs: Competition among repair providers leads to more competitive pricing.

- Faster turnaround times: Multiple repair providers can handle a larger volume of work, reducing wait times.

- Enhanced local support capabilities: Local repair shops can provide quicker and more convenient support for units stationed nearby.

Sustainable Practices

Right-to-Repair promotes environmentally responsible maintenance strategies.

- Reduced waste: Repairing equipment extends its lifespan, minimizing waste and resource consumption.

- Extended equipment lifespan: Proper maintenance and repair significantly extend the operational life of military equipment.

- Less reliance on new manufacturing: Reduced demand for new equipment lowers the environmental impact of production.

Technological Advancements Supporting Right-to-Repair in the Army

Technological innovations are playing a crucial role in the Army's adoption of Right-to-Repair principles.

Digital Manuals and Diagnostics

Digital platforms provide access to up-to-date repair manuals and advanced diagnostic software.

- Improved accessibility: Digital manuals are readily available to mechanics anywhere, anytime.

- Real-time troubleshooting: Diagnostic software assists in identifying and resolving equipment problems efficiently.

- Remote expert support: Mechanics can connect with experts remotely for assistance with complex repairs.

3D Printing for Parts Fabrication

3D printing allows for on-demand creation of replacement parts, reducing reliance on external suppliers.

- Reduced wait times: Critical parts can be printed quickly, minimizing equipment downtime.

- Immediate availability of critical parts: This is especially crucial in remote or challenging environments.

- Cost savings: 3D printing can be more cost-effective than traditional manufacturing for certain parts.

- Enhanced battlefield repair capabilities: The ability to fabricate parts in the field significantly enhances repair capabilities.

Augmented and Virtual Reality Training

Immersive technologies are revolutionizing training for Army mechanics.

- Improved training effectiveness: AR/VR simulations provide realistic training scenarios for complex repairs.

- Reduced training costs: Simulations can be significantly less expensive than hands-on training with actual equipment.

- Increased proficiency in complex repairs: Mechanics can practice challenging repairs in a safe and controlled environment.

Conclusion

The US Army's embrace of Right-to-Repair principles represents a crucial step toward a more efficient, cost-effective, and environmentally responsible maintenance system. By increasing access to repair information, fostering third-party repair options, and leveraging technological advancements, the Army is enhancing its readiness and minimizing its logistical burden. The continued implementation of Right-to-Repair strategies will undoubtedly enhance military capabilities and significantly influence future defense maintenance practices. Learn more about how the Army is spearheading the implementation of effective Right-to-Repair initiatives and explore the profound benefits of this transformative approach to military maintenance. Embrace the future of Army Repair with Right-to-Repair!

Featured Posts

-

Stephen Millers Character A Former Colleagues Account

May 18, 2025

Stephen Millers Character A Former Colleagues Account

May 18, 2025 -

True Crime Docuseries Outperforms Netflix Romance Drama On Top 10 List

May 18, 2025

True Crime Docuseries Outperforms Netflix Romance Drama On Top 10 List

May 18, 2025 -

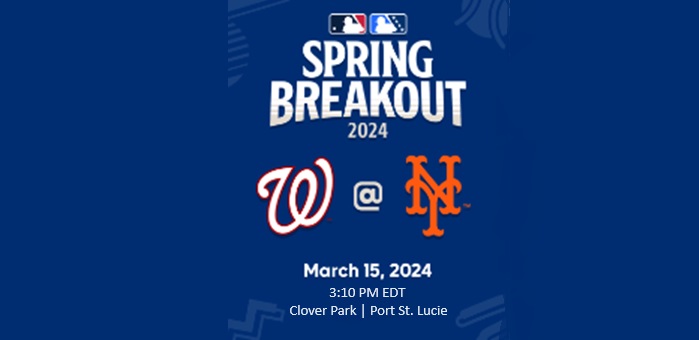

2025 Spring Breakout Unveiling The Rosters

May 18, 2025

2025 Spring Breakout Unveiling The Rosters

May 18, 2025 -

Check Daily Lotto Results For Tuesday 15th April 2025

May 18, 2025

Check Daily Lotto Results For Tuesday 15th April 2025

May 18, 2025 -

Generalka Srbije Pred Evrobasket U Minhenu Sve O Pripremnom Mecu

May 18, 2025

Generalka Srbije Pred Evrobasket U Minhenu Sve O Pripremnom Mecu

May 18, 2025