Solving OEM Supply Chain Problems: SG Wireless' Enhanced Manufacturing Strategy

Table of Contents

Proactive Component Sourcing and Inventory Management

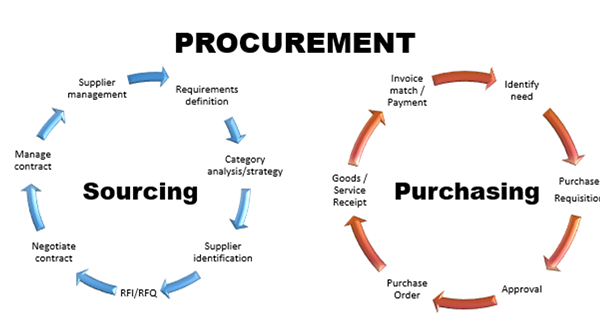

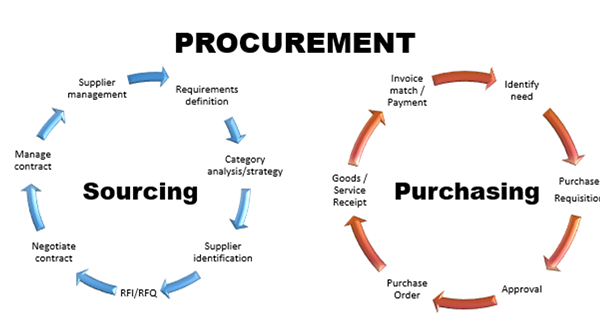

Securing the necessary components is the cornerstone of a stable OEM supply chain. SG Wireless employs a multi-faceted approach to proactive component sourcing and inventory management, mitigating risks associated with shortages and price volatility. Our strategy focuses on several key areas:

-

Strategic Supplier Diversification: We avoid reliance on single suppliers by establishing strategic partnerships with multiple, geographically diverse sources. This diversification minimizes the impact of disruptions affecting any one supplier. This robust approach to supplier relationship management is a critical element in overcoming OEM supply chain problems.

-

Advanced Demand Forecasting: We utilize sophisticated forecasting models, incorporating historical data, market trends, and machine learning algorithms to accurately predict future component demand. This allows us to optimize inventory levels, minimizing storage costs while ensuring sufficient stock to meet production needs. This precise forecasting directly addresses the unpredictability that plagues many OEMs.

-

Just-in-Time (JIT) Inventory System: To avoid unnecessary warehousing costs and the risk of obsolete inventory, we have implemented a robust JIT system. This ensures that components arrive precisely when needed, minimizing storage space and capital tied up in inventory. This efficient system directly tackles one of the biggest OEM supply chain problems.

-

Long-Term Supplier Agreements: We engage early with key suppliers to establish long-term agreements, securing priority access to crucial components and ensuring consistent supply. These agreements offer stability and predictability, a crucial antidote to volatile markets.

-

Data-Driven Risk Mitigation: We leverage data analytics to identify potential supply chain disruptions—be it geopolitical instability, natural disasters, or supplier capacity issues—allowing for proactive implementation of mitigation strategies. This proactive approach allows us to anticipate and avoid many common OEM supply chain problems.

Flexible and Agile Manufacturing Processes

Adaptability is crucial in today's dynamic environment. SG Wireless' manufacturing processes are designed for flexibility and agility, enabling us to respond effectively to changing component availability, fluctuating demand, and unexpected disruptions. This agility is a significant advantage in solving OEM supply chain problems.

-

Modular Design: Our products utilize a modular design approach, allowing for easy substitution of components based on availability. This flexibility minimizes the impact of component shortages and allows for swift adaptation to evolving customer requirements.

-

Advanced Manufacturing Technologies: We've invested in cutting-edge manufacturing technologies, including automation and robotics, to increase efficiency, improve precision, and enhance our ability to quickly adapt to changing production needs. This technological edge is vital in the fight against OEM supply chain problems.

-

Cross-Functional Teams: Dedicated cross-functional teams facilitate rapid problem-solving and decision-making in response to supply chain disruptions. This collaborative approach enables swift adjustments and minimizes downtime.

-

Lean Manufacturing Principles: We adhere to lean manufacturing principles, focusing on eliminating waste, optimizing workflows, and maximizing efficiency throughout the entire production process. This streamlined approach enhances our ability to address OEM supply chain problems swiftly and effectively.

-

Rapid Retooling Capacity: Our facilities are equipped for quick retooling and adaptation, enabling us to swiftly accommodate unexpected changes in demand or component specifications.

Strengthened Supplier Relationships and Collaboration

Building strong, collaborative relationships with our suppliers is paramount to overcoming OEM supply chain problems. Our approach is based on open communication, mutual trust, and a shared commitment to success.

-

Close Collaboration and Transparency: We maintain close collaboration with key suppliers, ensuring transparency and early warning of potential issues. This proactive communication is crucial for effective risk management.

-

Joint Risk Mitigation Strategies: We develop and implement joint risk mitigation strategies with our suppliers, collaboratively addressing potential disruptions before they impact production. This shared responsibility is key to stability.

-

Open Communication Channels: Open communication channels ensure timely problem resolution and the maintenance of consistent supply. Quick responses and open dialogue are integral to overcoming supply chain challenges.

-

Continuous Improvement Initiatives: Regular performance reviews and continuous improvement initiatives strengthen supplier relationships and drive ongoing performance enhancements. This commitment to improvement is vital in navigating the complexities of OEM supply chain problems.

-

Ethical Sourcing Practices: We adhere to fair and ethical sourcing practices, fostering long-term partnerships built on mutual respect and trust.

Transparency and Real-Time Tracking

Visibility into the supply chain is critical. We utilize advanced tracking systems to monitor component movement and production progress in real-time, providing clients with transparent and regular updates on order status and potential delays. Our data dashboards and reporting tools ensure clear visibility into the entire supply chain, allowing for proactive management and minimized disruptions. This transparency and proactive communication are integral to effectively addressing OEM supply chain problems.

Conclusion

SG Wireless' enhanced manufacturing strategy offers a compelling solution to the persistent OEM supply chain problems plaguing the industry. By proactively managing components, maintaining agile processes, and fostering strong supplier relationships, SG Wireless delivers reliable and predictable production, helping businesses overcome the challenges of today's volatile market. Addressing OEM supply chain problems effectively is key to success. Contact SG Wireless today to learn how our innovative approach can help your business thrive and overcome the challenges of OEM supply chain issues.

Featured Posts

-

Van Der Poel Calls For Legal Action After Paris Roubaix Bottle Attack

May 26, 2025

Van Der Poel Calls For Legal Action After Paris Roubaix Bottle Attack

May 26, 2025 -

La Rtbf Inaccessible Comprendre Les Restrictions Geographiques

May 26, 2025

La Rtbf Inaccessible Comprendre Les Restrictions Geographiques

May 26, 2025 -

Elon Musks Influence On Dogecoin A Shifting Landscape

May 26, 2025

Elon Musks Influence On Dogecoin A Shifting Landscape

May 26, 2025 -

Tour Of Flanders 2024 Pogacar Secures Second Victory Outpaces Van Der Poel

May 26, 2025

Tour Of Flanders 2024 Pogacar Secures Second Victory Outpaces Van Der Poel

May 26, 2025 -

Flash Flood Emergency Response Plan A Step By Step Guide

May 26, 2025

Flash Flood Emergency Response Plan A Step By Step Guide

May 26, 2025