Sustainable Steel Production: Eramet's EraLow's Contribution To Decarbonization

Table of Contents

Eramet, a leading global mining and metallurgical group, is at the forefront of the sustainable steel revolution with its pioneering eraLow® technology. This process represents a significant advancement in sustainable steelmaking, offering a pathway towards a more environmentally friendly future for the steel industry. This article will explore how eraLow® is making a tangible contribution to the decarbonization of steel production, focusing on its environmental impact, economic viability, and future potential.

The Environmental Impact of Traditional Steel Production

Traditional blast furnace steelmaking is an energy-intensive process with a substantial environmental impact.

High Carbon Footprint

The use of coal and coke in blast furnaces generates vast quantities of greenhouse gases. These fossil fuels are crucial for the high-temperature reduction of iron ore, but their combustion releases significant amounts of carbon dioxide (CO2) into the atmosphere.

Greenhouse Gas Emissions

The steel industry is a major emitter of greenhouse gases, contributing significantly to climate change. Besides CO2, traditional methods release other harmful gases, including methane (CH4) and nitrous oxide (N2O), further exacerbating the environmental problem.

- Traditional steelmaking emits approximately 1.8 to 2.5 tonnes of CO2 per tonne of crude steel produced.

- Beyond CO2, air pollution from particulate matter and sulfur oxides, as well as water pollution from process waste, are significant environmental concerns.

- Stringent environmental regulations and growing public pressure are forcing the steel industry to rapidly decarbonize its operations.

Eramet's eraLow®: A Technological Breakthrough in Sustainable Steel Production

Eramet's eraLow® process offers a groundbreaking solution to the environmental challenges of traditional steelmaking.

Innovative Process

eraLow® leverages a fundamentally different approach, significantly reducing reliance on fossil fuels. The core principle involves using hydrogen or other low-carbon energy sources to reduce iron ore, thereby drastically cutting CO2 emissions. This innovative process represents a paradigm shift in sustainable steelmaking.

Key Features and Advantages

The sustainability of eraLow® is underpinned by several key features:

- It utilizes hydrogen, a clean energy carrier, or other low-carbon alternatives as a reducing agent, minimizing CO2 emissions.

- Eramet reports a significant reduction in CO2 emissions compared to traditional methods, with the potential for near-zero emissions depending on the energy mix used. Specific figures vary depending on the implementation and energy source but are substantially lower than traditional methods.

- By reducing reliance on coal and coke, eraLow® also minimizes air and water pollution associated with traditional blast furnace operations.

- The modular design of eraLow® allows for scalability and adaptation to various production capacities, enabling its widespread adoption across the steel industry.

The Economic Viability and Market Potential of Sustainable Steel

The transition to sustainable steel production is not just an environmental imperative; it also presents significant economic opportunities.

Growing Demand for Green Steel

Consumer preferences are shifting towards environmentally friendly products, driving increased demand for low-carbon steel. Furthermore, stringent environmental regulations and ambitious corporate sustainability goals are compelling businesses to source green steel.

Competitive Advantage of eraLow®

Eramet's eraLow® technology positions the company competitively within this evolving market landscape.

- Government incentives and subsidies are increasingly being offered to support green steel production, making eraLow® even more economically attractive.

- Reduced emissions and improved efficiency lead to long-term cost savings, enhancing profitability.

- Adopting sustainable steel production technologies like eraLow® gives companies a significant competitive advantage, unlocking increased market share and brand reputation.

Future Directions and Collaboration in Sustainable Steelmaking

Eramet is committed to continuous improvement and collaboration in the quest for sustainable steelmaking.

Research and Development

Eramet's ongoing R&D efforts focus on further optimizing the eraLow® process to minimize its environmental impact and enhance its efficiency.

Industry Partnerships and Collaboration

Eramet actively collaborates with various stakeholders to promote widespread adoption of sustainable steelmaking practices.

- Future plans include exploring further technological advancements in eraLow®, potentially integrating carbon capture and storage technologies.

- Partnerships with leading steel producers, prominent research institutions, and governmental organizations are vital for accelerating the transition to a more sustainable steel industry.

- Collaboration is key to creating a resilient and sustainable steel supply chain, ensuring the long-term viability of green steel production.

Sustainable Steel Production: Eramet's eraLow® – A Path to a Greener Future

Eramet's eraLow® technology is a pivotal contribution to reducing the environmental impact of steel production. Its innovative process offers a viable and economically advantageous pathway toward a cleaner, more sustainable future for the steel industry. The environmental, economic, and competitive benefits of eraLow® are substantial, making it a crucial technology for the global transition to green steel.

Invest in a sustainable future with eraLow®. Learn more about Eramet's commitment to sustainable steel production and its groundbreaking eraLow® technology by visiting [link to Eramet's website].

Featured Posts

-

Examining Tylas Chanel Style A Fashion Analysis

May 14, 2025

Examining Tylas Chanel Style A Fashion Analysis

May 14, 2025 -

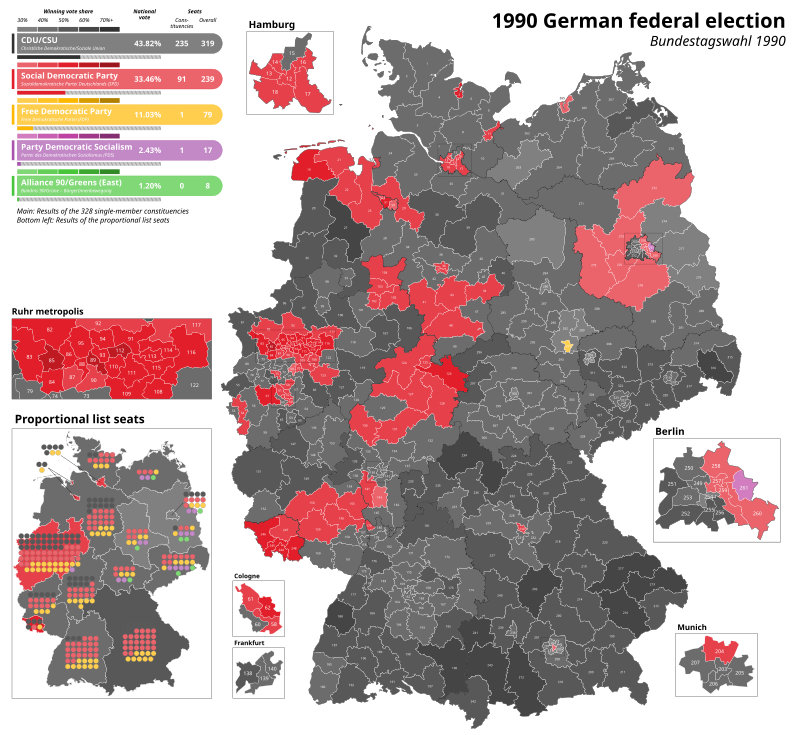

German Federal Election Turning The Tide Is It Too Late

May 14, 2025

German Federal Election Turning The Tide Is It Too Late

May 14, 2025 -

Las Presentaciones De Joaquin Caparros Con El Sevilla Fc 25 Anos De Trayectoria

May 14, 2025

Las Presentaciones De Joaquin Caparros Con El Sevilla Fc 25 Anos De Trayectoria

May 14, 2025 -

Analyzing The Brand Impact Sinner Vs Federers Iconic Rf

May 14, 2025

Analyzing The Brand Impact Sinner Vs Federers Iconic Rf

May 14, 2025 -

Giovannina Orsino Dal Successo Al Ruolo Di Tintoria Ufficiale A Sanremo

May 14, 2025

Giovannina Orsino Dal Successo Al Ruolo Di Tintoria Ufficiale A Sanremo

May 14, 2025