The Art Of Cricket Bat Making: A Living Heritage

Table of Contents

Selecting the Perfect Willow

The journey of cricket bat making begins with the selection of the perfect willow. The choice of willow directly impacts the bat's performance, durability, and ultimately, its price. English Willow and Kashmir Willow are the most prized varieties, each possessing unique characteristics. High-quality willow is characterized by its exceptionally close grain, giving it incredible strength and resilience, crucial for withstanding the impact of powerful shots.

- Grading systems for willow: Willow is graded based on its grain density and straightness, with Grade 1 representing the highest quality. These grades significantly influence the bat's price and performance.

- Source and sustainability of willow trees: Sustainable sourcing is becoming increasingly important. Reputable bat makers prioritize responsible forestry practices to ensure a long-term supply of high-quality willow.

- Impact of climate and growing conditions on willow quality: The climate and soil conditions where the willow tree grows significantly affect the wood's density and grain structure. Optimal conditions produce the finest willow for cricket bat making.

The Shaping and Carving Process

Once the perfect willow cleft is selected, the meticulous process of shaping and carving begins. This stage demands both traditional craftsmanship and modern precision. Experienced bat makers use specialized tools, including hand tools and lathes, to meticulously carve the willow, creating the distinctive profile and curves of the cricket bat.

- Using specialized hand tools and lathes: Traditional hand tools allow for intricate shaping, while modern lathes ensure precision and consistency. A combination of both is often employed.

- Creating the unique profile and curves of the bat: The shaping process requires a keen eye for detail, creating the sweet spot and ensuring optimal balance for the player.

- Precision and attention to detail required at each stage: Even minor imperfections can significantly impact the bat's performance, emphasizing the skill and experience required at this crucial phase of cricket bat making.

The Crucial Role of the Handle (Cane)

The handle, typically made from cane, is just as crucial as the blade in a cricket bat. The cane's flexibility and grip significantly influence the feel and performance of the bat. Sarawak cane, known for its strength and resilience, is a popular choice.

- Types of cane (e.g., Sarawak cane): Different types of cane offer varying levels of flexibility and shock absorption. The choice depends on the player's preference and playing style.

- The process of preparing and shaping the cane: The cane undergoes a careful preparation process, including steaming and shaping, to ensure a secure and comfortable grip.

- Methods for securing the cane to the blade (e.g., using glue and pressing): Advanced techniques ensure a strong and lasting bond between the handle and the blade, crucial for the bat's longevity.

Finishing Touches and Quality Control

The final stages of cricket bat making involve meticulous sanding and polishing to create a smooth, polished finish. A grip is then added, enhancing comfort and control. Rigorous quality control measures are vital throughout the process.

- Types of finishes and their impact on durability: Different finishes provide varying levels of protection against moisture and wear, influencing the bat's lifespan.

- Checking for imperfections and defects: Thorough inspection at every stage is vital to ensure the bat meets the high standards of performance and durability.

- The role of quality control in maintaining reputation: A reputation for quality is paramount in the cricket bat making industry, driving the commitment to stringent quality control procedures.

The Evolution of Cricket Bat Making

Cricket bat making has evolved significantly over time. While traditional techniques remain important, the introduction of modern technology and materials has refined the process. The craft has seen innovation in materials, tools, and techniques, enhancing both the performance and the aesthetics of the bats.

- Traditional methods versus modern techniques: A blend of traditional handcrafting and modern precision tools creates the perfect balance between craftsmanship and efficiency.

- Introduction of new materials and technologies: While willow remains the core material, advancements in materials science have led to the exploration of innovative approaches to enhance bat performance.

- Notable bat makers and their legacies: Many skilled artisans have contributed to the evolution of cricket bat making, passing down their knowledge and expertise through generations.

Conclusion

The art of cricket bat making is a testament to human skill, precision, and enduring tradition. From selecting the perfect willow to adding the final touches, each stage requires meticulous attention to detail. The process showcases a remarkable blend of traditional craftsmanship and modern innovation. Discover the artistry and tradition behind cricket bat making and support the skilled artisans who keep this heritage alive. Learn more about the fascinating world of cricket bat making and find a handcrafted bat that perfectly complements your game.

Featured Posts

-

Big Rig Rock Report 3 12 On Rock 106 1 Trucking Insights And Updates

May 23, 2025

Big Rig Rock Report 3 12 On Rock 106 1 Trucking Insights And Updates

May 23, 2025 -

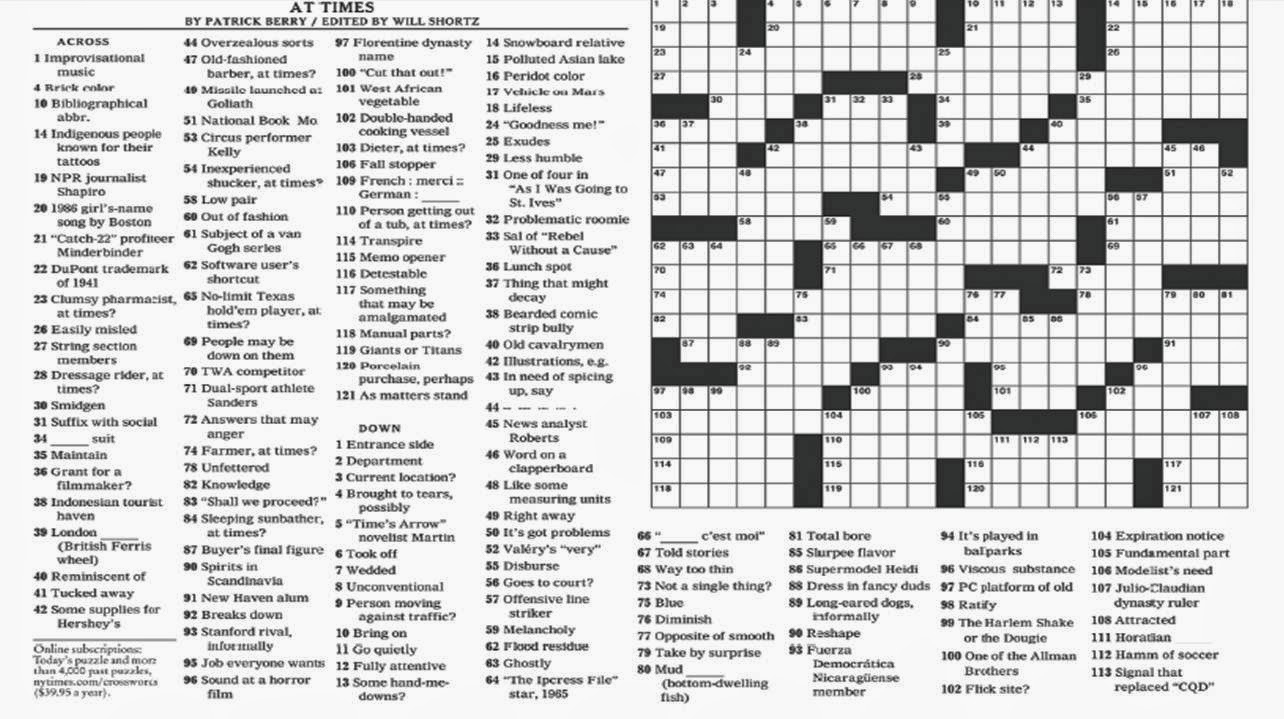

Nyt Mini Crossword May 1st Solution Marvel The Avengers Clue Explained

May 23, 2025

Nyt Mini Crossword May 1st Solution Marvel The Avengers Clue Explained

May 23, 2025 -

Tu Horoscopo Semanal 11 17 De Marzo De 2025

May 23, 2025

Tu Horoscopo Semanal 11 17 De Marzo De 2025

May 23, 2025 -

Elena Rybakina Uspeshnoe Vystuplenie Na Turnire V Rime

May 23, 2025

Elena Rybakina Uspeshnoe Vystuplenie Na Turnire V Rime

May 23, 2025 -

Essen Der Unerwartete Eis Trend In Nordrhein Westfalen

May 23, 2025

Essen Der Unerwartete Eis Trend In Nordrhein Westfalen

May 23, 2025