The Auto Industry's Ongoing Battle Against Electric Vehicle Requirements

Table of Contents

The Economic Hurdles of EV Adoption

The shift towards electric vehicles (EVs) presents substantial economic hurdles for the auto industry. High upfront investment costs, supply chain disruptions, and consumer affordability concerns are all significant factors influencing the pace of adoption.

High Initial Investment Costs

The transition to EV manufacturing requires a massive upfront investment. Automakers face significant expenses in several key areas:

- High R&D costs: Developing new battery technologies, electric powertrains, and associated software requires substantial research and development expenditure.

- Expensive battery production: Lithium-ion batteries, currently the dominant technology, are expensive to produce, representing a significant portion of the overall EV cost. Scaling up production to meet growing demand further increases costs.

- Factory modernization expenses: Existing automobile factories need significant retooling and modernization to adapt to EV production lines, a process that is both costly and time-consuming.

- Potential for low initial return on investment: The high initial investment may not yield immediate returns, especially in the early stages of EV market penetration. This creates a financial risk for automakers.

Supply Chain Disruptions

The production of EVs relies heavily on a complex and global supply chain. Several factors contribute to significant supply chain disruptions:

- Lithium-ion battery component shortages: The demand for lithium, cobalt, nickel, and other critical battery materials is far outpacing supply, leading to shortages and price volatility.

- Reliance on specific geographical regions for raw materials: Many key raw materials are concentrated in specific regions, creating vulnerabilities to geopolitical instability and trade disputes.

- Geopolitical instability impacting supply chains: International conflicts, political tensions, and trade wars can significantly disrupt the flow of vital components, impacting EV production timelines and costs.

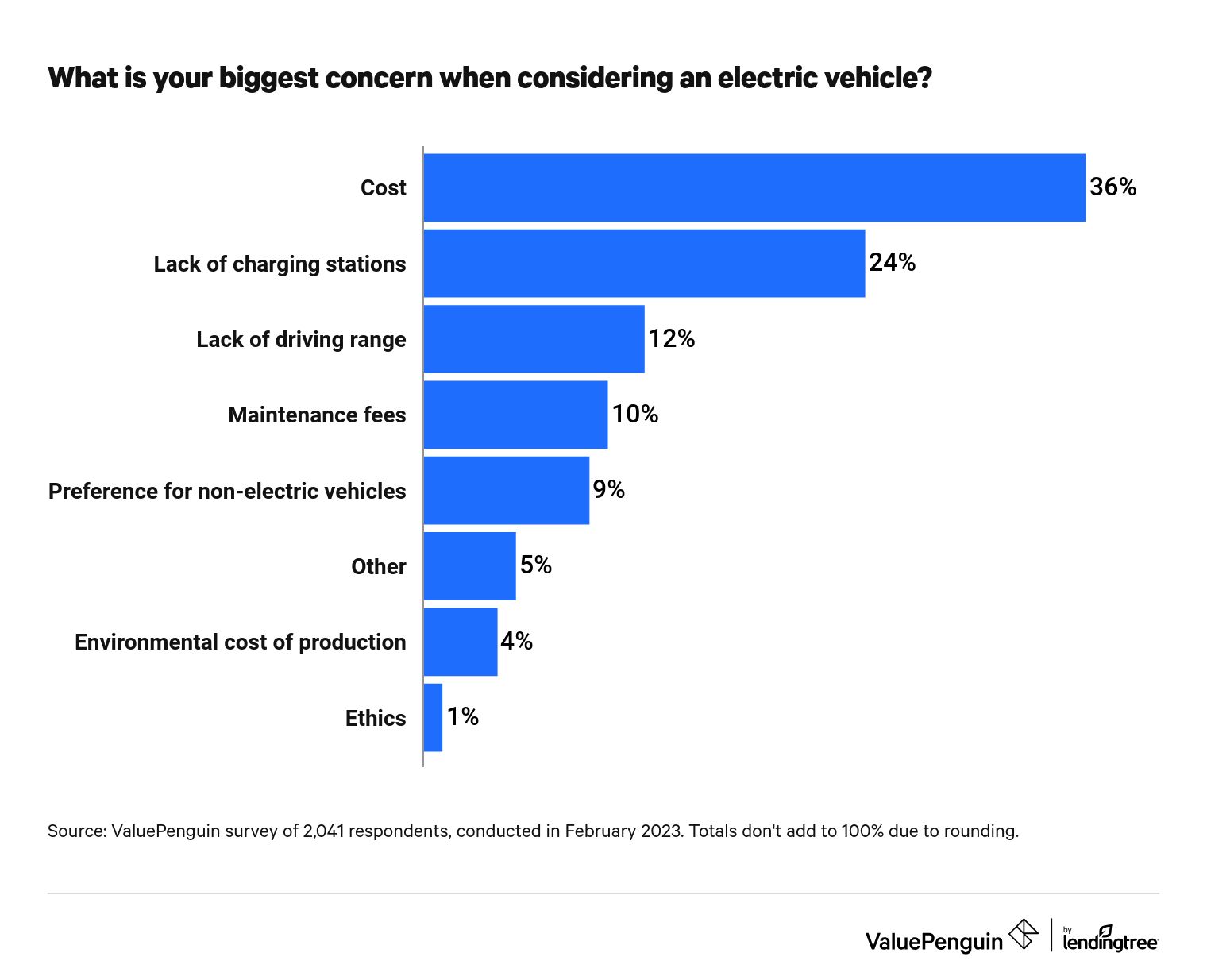

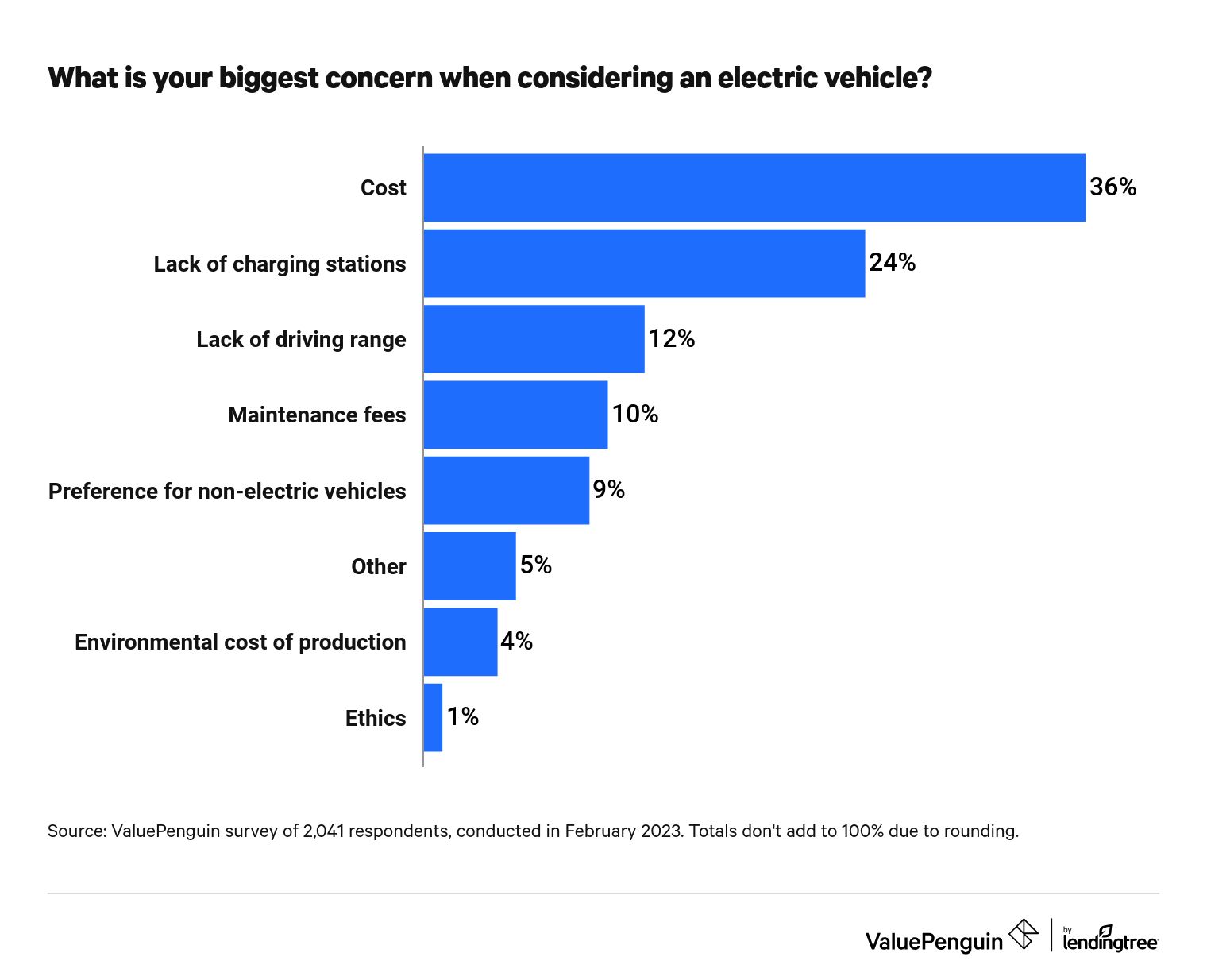

Consumer Affordability and Market Acceptance

Despite growing interest, the higher purchase price of EVs compared to traditional gasoline-powered vehicles remains a barrier to mass adoption. Several factors impact consumer acceptance:

- Higher initial purchase price of EVs: The cost of batteries and other EV components contributes to higher upfront costs, making EVs less accessible to many consumers.

- Limited range anxiety: Concerns about the driving range of EVs and the availability of charging stations remain a significant obstacle.

- Lack of widespread charging infrastructure: The inadequate deployment of public charging stations, particularly in rural areas, inhibits EV adoption.

- Consumer perception of EV technology: Addressing misconceptions and concerns around EV performance, charging times, and maintenance is crucial for building consumer confidence.

Technological Challenges in Meeting EV Standards

Beyond economic hurdles, the auto industry faces significant technological challenges in meeting increasingly stringent electric vehicle requirements.

Battery Technology Advancements

Continuous advancements in battery technology are crucial for broader EV adoption. Key areas requiring improvement include:

- Research and development in solid-state batteries: Solid-state batteries promise higher energy density, faster charging, and improved safety compared to current lithium-ion batteries.

- Improvements in battery management systems: Advanced battery management systems are crucial for optimizing battery performance, lifespan, and safety.

- Exploring alternative battery chemistries: Research into alternative battery chemistries beyond lithium-ion is essential for reducing reliance on scarce and expensive materials.

Charging Infrastructure Development

The lack of widespread and reliable charging infrastructure significantly limits EV adoption. Significant efforts are needed to:

- Government incentives for charging station deployment: Governments play a crucial role in incentivizing the deployment of public charging stations through subsidies, tax credits, and other support mechanisms.

- Private sector investment in charging infrastructure: Private companies are increasingly investing in building and operating charging networks, but significant expansion is still required.

- Challenges in integrating different charging standards: The lack of standardized charging technologies across different countries and regions creates interoperability challenges.

Regulatory Compliance and Standards

Navigating the complex and often varying regulations across different regions is a significant challenge for global automakers:

- Emissions standards variations: Different countries and regions have varying emission standards, creating complexities for manufacturers designing vehicles for multiple markets.

- Safety regulations specific to EVs: Unique safety regulations for electric vehicles, addressing issues like battery safety and electrical systems, add to the complexity.

- Different charging standards and protocols: Inconsistent charging standards across regions require manufacturers to adapt their vehicles to different charging systems.

- Trade barriers and tariffs: International trade barriers and tariffs on EV components and finished vehicles can increase costs and complicate global production strategies.

The Shifting Landscape of the Automotive Workforce

The transition to electric vehicles necessitates significant changes in the automotive workforce.

Reskilling and Training Initiatives

The industry needs to adapt its workforce to the skills required for EV production and maintenance:

- Investment in training programs: Automakers and governments must invest heavily in training programs to equip workers with the skills needed for EV manufacturing, maintenance, and repair.

- Partnerships with educational institutions: Collaboration between industry and educational institutions is crucial to develop relevant curricula and training programs.

- Attracting skilled engineers and technicians: The industry needs to attract and retain skilled engineers and technicians with expertise in electric vehicle technologies.

Job Displacement and Economic Transition

The shift away from internal combustion engine (ICE) vehicles will inevitably lead to job displacement in some areas:

- Government support for workers impacted by industry changes: Governments have a crucial role to play in providing support and retraining programs for workers displaced by the transition.

- Retraining programs to ease transitions: Effective retraining programs can help workers transition to new roles within the automotive industry or related sectors.

- Exploring new job opportunities in the EV sector: The growth of the EV sector creates new job opportunities in areas like battery production, charging infrastructure development, and software engineering.

Conclusion

The auto industry faces a multitude of challenges in complying with increasingly stringent electric vehicle requirements. Economic hurdles, technological complexities, and the need for workforce transitions all demand collaborative efforts. Overcoming these obstacles requires significant investment in research and development, infrastructure development, and workforce training. Collaboration between governments, automakers, and technology companies is crucial to accelerate the transition to sustainable transportation and achieve the goals of reducing carbon emissions. Understanding the complexities surrounding electric vehicle requirements is crucial for navigating the future of the automotive industry. Stay informed and engaged as this dynamic sector continues to evolve.

Featured Posts

-

Professional Hair And Tattoo Artists Behind Ariana Grandes New Look

Apr 27, 2025

Professional Hair And Tattoo Artists Behind Ariana Grandes New Look

Apr 27, 2025 -

Wta Finals Austria And Singapore Set For Showdowns

Apr 27, 2025

Wta Finals Austria And Singapore Set For Showdowns

Apr 27, 2025 -

Napoleon Ceo Emphasis On Buying Canadian Goods

Apr 27, 2025

Napoleon Ceo Emphasis On Buying Canadian Goods

Apr 27, 2025 -

Kalinskaya Upsets Keys In Charleston Quarterfinal Clash

Apr 27, 2025

Kalinskaya Upsets Keys In Charleston Quarterfinal Clash

Apr 27, 2025 -

Section 230 And Banned Chemicals On E Bay A Judges Ruling

Apr 27, 2025

Section 230 And Banned Chemicals On E Bay A Judges Ruling

Apr 27, 2025

Latest Posts

-

Actors And Writers Strike The Complete Impact On Hollywood

Apr 28, 2025

Actors And Writers Strike The Complete Impact On Hollywood

Apr 28, 2025 -

Hollywood Shut Down Double Strike Impacts Film And Television Production

Apr 28, 2025

Hollywood Shut Down Double Strike Impacts Film And Television Production

Apr 28, 2025 -

Hollywood Strike Actors Join Writers Bringing Industry To A Standstill

Apr 28, 2025

Hollywood Strike Actors Join Writers Bringing Industry To A Standstill

Apr 28, 2025 -

Cocaine Found At White House Secret Service Investigation Results

Apr 28, 2025

Cocaine Found At White House Secret Service Investigation Results

Apr 28, 2025 -

Secret Service Completes Probe Of Cocaine Discovery At White House

Apr 28, 2025

Secret Service Completes Probe Of Cocaine Discovery At White House

Apr 28, 2025