The Feasibility Of Restoring Manufacturing Jobs In America

Table of Contents

Economic Factors Influencing Reshoring

Several economic factors significantly impact the ability to reshore manufacturing jobs to the United States.

Automation and Technological Advancements: Automation in manufacturing, while boosting productivity, presents a double-edged sword.

- Robotics in manufacturing and other advanced technologies have increased efficiency but also displaced many low-skilled workers.

- This job displacement underscores the urgent need for workforce retraining and upskilling initiatives focusing on automation and robotics expertise.

- However, automation also creates new, high-skilled jobs in areas like engineering, programming, and maintenance of these sophisticated systems. The skills gap, therefore, needs addressing proactively.

Labor Costs and Competitiveness: American labor costs remain a significant hurdle in competing with countries like China and Vietnam.

- Wage differences, coupled with benefits and regulatory costs in the US, often make manufacturing more expensive domestically.

- However, focusing on increased productivity and efficiency can help offset these higher labor costs. Investing in advanced technologies to improve output per worker is a critical strategy.

- The equation of labor costs needs to be examined in the context of overall manufacturing competitiveness, which also includes factors such as infrastructure, energy costs, and access to skilled labor.

Government Policies and Incentives: Government policies play a crucial role in incentivizing reshoring.

- Tax breaks for manufacturing, subsidies for investment in new technologies, and strategic trade policies can all help make domestic production more attractive.

- The effectiveness of these government incentives varies greatly depending on their design and implementation. Well-targeted initiatives are more likely to succeed.

- Conversely, poorly designed government intervention can distort markets and lead to unintended consequences.

Supply Chain Resilience and Reshoring Strategies

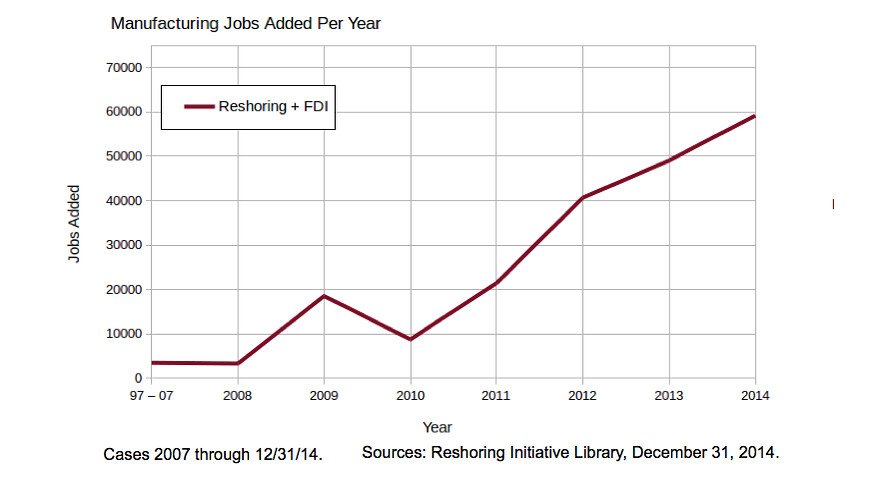

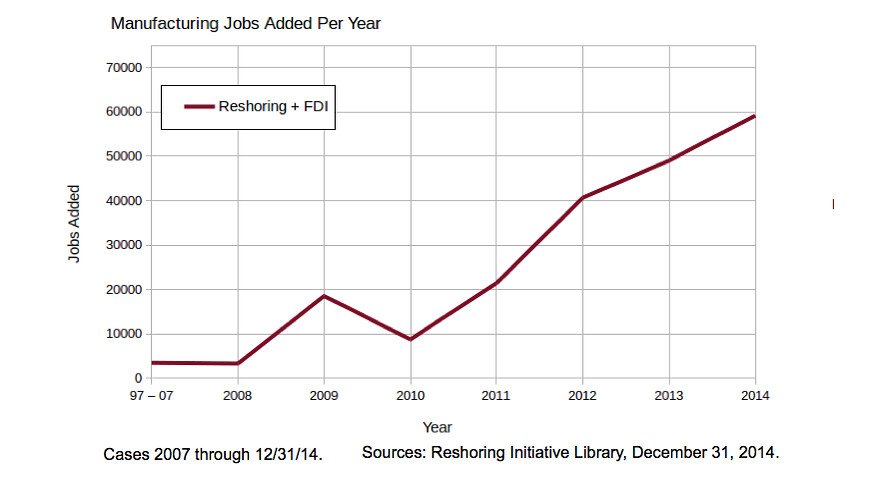

Recent global events have highlighted the vulnerabilities of relying heavily on global supply chains.

Risks of Global Supply Chains: The COVID-19 pandemic and geopolitical instability vividly demonstrated the fragility of globalized manufacturing.

- Supply chain disruptions caused significant economic damage and underscored the need for greater resilience.

- The costs of relying on foreign suppliers, including transportation delays, political risks, and potential disruptions, have become increasingly apparent.

- This has sparked renewed interest in supply chain diversification and a move towards domestic manufacturing to reduce reliance on single points of failure.

Nearshoring and Regionalization: Nearshoring—moving manufacturing to countries closer to the US, like Mexico or Canada—offers a middle ground.

- Nearshoring offers benefits such as reduced transportation costs and shorter lead times compared to sourcing from Asia.

- However, it might not fully address all the concerns of global supply chain vulnerabilities.

- Regional economic development strategies can play a significant role in facilitating nearshoring and attracting manufacturing clusters to specific regions. This approach fosters collaboration and shared resources.

The Role of Education and Workforce Development

Investing in education and workforce development is paramount for a successful resurgence in American manufacturing.

Skills Gaps and Training Programs: The modern manufacturing sector requires a highly skilled workforce.

- A significant skills gap exists, requiring robust apprenticeship programs, community college initiatives, and vocational schools focused on manufacturing technologies.

- Government investment in STEM education is crucial to create a pipeline of talent capable of operating and maintaining advanced machinery.

- These programs must adapt to the rapidly evolving technological landscape to ensure that workers possess the skills needed for the jobs of the future.

Attracting and Retaining Talent: Attracting young people to manufacturing careers and retaining experienced workers is equally important.

- Improving the image of manufacturing jobs, moving away from outdated perceptions of dirty and dangerous work, is vital.

- Offering competitive wages and benefits packages, and creating a positive and supportive workplace culture, will attract and retain talent.

- Investing in employee development and providing opportunities for career advancement can also significantly contribute to retention.

Conclusion:

Restoring American manufacturing jobs presents significant challenges but also offers substantial opportunities. While economic factors like labor costs and global competition need to be carefully considered, advancements in automation, strategic government policies, and a resilient supply chain strategy (including nearshoring) are all crucial elements. The development of a skilled workforce through targeted education and training initiatives is paramount. Investing in American manufacturing, supporting reshoring initiatives, and exploring career opportunities in the revitalized manufacturing sector are essential steps towards a more robust and competitive American economy. Let's work together to build a thriving future for American manufacturing and its workforce.

Featured Posts

-

Ivoire Tech Forum 2025 A Abidjan Un Rendez Vous Majeur Pour La Strategie Numerique

May 20, 2025

Ivoire Tech Forum 2025 A Abidjan Un Rendez Vous Majeur Pour La Strategie Numerique

May 20, 2025 -

Michael Strahans Departure From Good Morning America The Real Reason

May 20, 2025

Michael Strahans Departure From Good Morning America The Real Reason

May 20, 2025 -

Exploring The World Of Agatha Christies Poirot

May 20, 2025

Exploring The World Of Agatha Christies Poirot

May 20, 2025 -

Rashfords Two Goals Secure Manchester Uniteds Fa Cup Win Over Aston Villa

May 20, 2025

Rashfords Two Goals Secure Manchester Uniteds Fa Cup Win Over Aston Villa

May 20, 2025 -

Fieldview Care Home Dernieres Informations Concernant L Enquete Sur Les Allegations D Abus

May 20, 2025

Fieldview Care Home Dernieres Informations Concernant L Enquete Sur Les Allegations D Abus

May 20, 2025