Addressing The Challenges Of Robotic Nike Shoe Production

Table of Contents

High Initial Investment Costs and ROI Concerns

The transition to robotic shoe production requires a substantial upfront investment. This includes not only the purchase of advanced robotic arms and automation software but also the costs associated with installation, integration with existing infrastructure, and ongoing maintenance. Achieving a positive return on investment (ROI) within a reasonable timeframe presents a significant challenge for Nike.

- Cost of advanced robotic arms and automation software: State-of-the-art robotic systems capable of handling the complexities of shoe manufacturing are expensive. The cost of purchasing and implementing these systems can run into millions of dollars.

- Integration with existing production infrastructure: Integrating new robotic systems into existing production lines requires significant modifications and adjustments to the factory layout and workflow. This adds to the overall cost and complexity of the implementation.

- Need for skilled technicians for maintenance and programming: Robotic systems require specialized maintenance and programming expertise. Finding and retaining skilled technicians is crucial for minimizing downtime and maximizing the efficiency of the robotic systems. This adds to labor costs.

- Potential for unforeseen downtime and repair costs: Despite careful planning, unexpected breakdowns and repairs can occur. These unforeseen events can significantly impact production schedules and increase overall costs.

A thorough Total Cost of Ownership (TCO) analysis is essential before implementing robotic systems. This analysis should encompass all aspects of the investment, including initial costs, operational expenses, and potential maintenance and repair costs, to accurately assess the long-term financial implications.

Complexity of Shoe Manufacturing and Adaptability of Robots

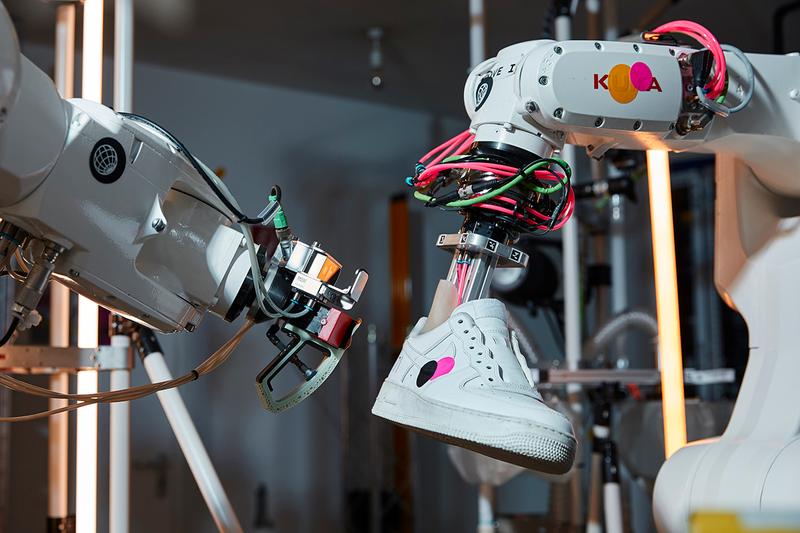

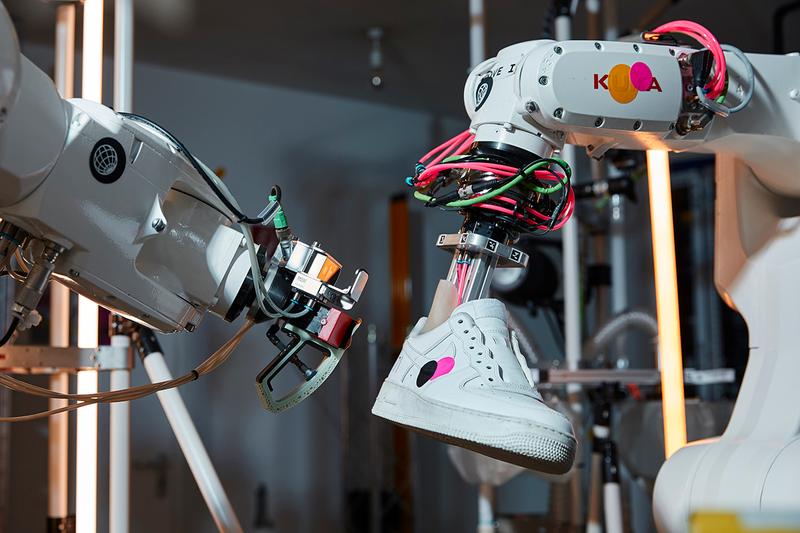

Shoe manufacturing is an intricate process involving numerous steps and a variety of materials. From cutting and stitching to gluing and assembling, each stage presents unique challenges for robotic automation. Adapting robots to handle the delicate and varied tasks involved in shoe production requires significant technological advancements.

- Challenges in programming robots for precision tasks like stitching intricate patterns: The precision required for stitching complex patterns in shoe uppers necessitates highly sophisticated programming and control systems. Developing robots capable of achieving this level of accuracy is a significant technical hurdle.

- Adapting robotic grippers to handle diverse materials (leather, synthetic fabrics, soles): Shoe manufacturing utilizes a wide range of materials with differing properties. Developing robotic grippers capable of handling these diverse materials without damaging them is a considerable challenge.

- Ensuring consistency and quality control in automated processes: Maintaining consistency and quality in automated processes is crucial. Developing robust quality control mechanisms for robotic shoe production is essential to ensure that the finished products meet Nike's high standards.

- Difficulty in adapting to design changes and new shoe models: Nike regularly introduces new shoe designs and models. Adapting robotic systems to accommodate these changes requires reprogramming and retooling, which can be both time-consuming and expensive.

Job Displacement and Workforce Reskilling

The introduction of robotic automation in Nike's factories raises concerns about job displacement. However, this challenge can be mitigated through proactive workforce planning and reskilling initiatives. By investing in training programs, Nike can upskill its employees for new roles in robotic maintenance, programming, and system management.

- Importance of proactive workforce planning and retraining initiatives: Nike needs to proactively identify potential job displacement and implement comprehensive retraining programs to prepare its workforce for the changes brought about by automation.

- Development of new roles related to robotic systems in manufacturing: The integration of robotics creates new job opportunities in areas such as robotic maintenance, programming, and system management. Nike can invest in creating these new roles and providing the necessary training for its employees.

- Addressing employee concerns and anxieties about job security: Open communication and transparency are essential to address employee concerns and anxieties related to job security. Nike needs to engage its workforce in the transition process and provide support and reassurance.

- Investing in education and training partnerships: Collaborating with educational institutions and training providers can help Nike develop customized training programs to equip its workforce with the skills needed to thrive in the new automated environment.

Ethical Considerations of Robotic Automation in Manufacturing

The ethical implications of widespread automation in the shoe industry cannot be ignored. While robotic automation offers potential benefits in terms of efficiency and productivity, it also raises concerns about job losses and the social responsibility of Nike. However, robots also offer the potential to improve working conditions by eliminating repetitive and hazardous tasks.

- Balancing the benefits of automation with the potential negative impacts on employment: Nike needs to carefully consider the potential social and economic consequences of automation and develop strategies to mitigate any negative impacts on its workforce.

- Nike's corporate social responsibility initiatives related to automation and workforce transition: Transparency and proactive engagement are key components of Nike’s responsibility to its employees during this period of technological advancement.

- The future of work in the footwear industry in light of robotic automation: The future of work in the footwear industry will need to incorporate a thoughtful blend of human expertise and robotic capabilities.

Conclusion

The integration of robotics in Nike shoe production offers significant potential for increased efficiency and scalability. However, high initial investment costs, the complexity of adapting robots to intricate manufacturing processes, and the potential for job displacement present serious challenges. Addressing these issues through careful planning, strategic investment in workforce development, and a focus on responsible automation is crucial for Nike to successfully implement robotic systems. Overcoming these challenges will unlock the true potential of robotic automation in Nike's robotic shoe production future. Continued research and development are essential to refine these technologies and minimize negative consequences.

Featured Posts

-

Blue Origin And Katy Perry A Comparative Analysis Of Public Perception After Setbacks

Apr 22, 2025

Blue Origin And Katy Perry A Comparative Analysis Of Public Perception After Setbacks

Apr 22, 2025 -

Google And Doj Return To Court Battle Over Search Monopoly Heats Up

Apr 22, 2025

Google And Doj Return To Court Battle Over Search Monopoly Heats Up

Apr 22, 2025 -

Trumps Trade Wars A Threat To Us Financial Leadership

Apr 22, 2025

Trumps Trade Wars A Threat To Us Financial Leadership

Apr 22, 2025 -

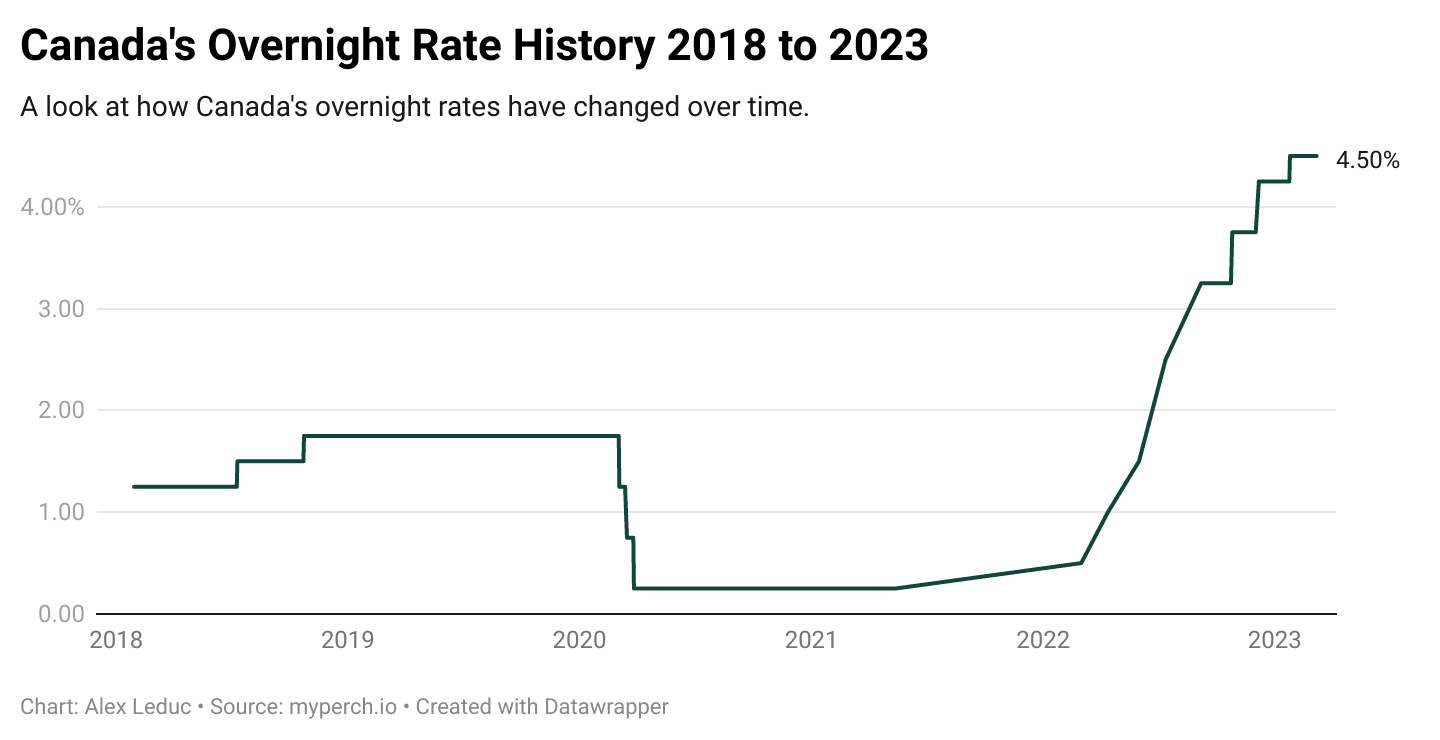

Bank Of Canada Rate Pause Expert Analysis From Fp Video

Apr 22, 2025

Bank Of Canada Rate Pause Expert Analysis From Fp Video

Apr 22, 2025 -

From Scatological Data To Engaging Podcast An Ai Powered Solution

Apr 22, 2025

From Scatological Data To Engaging Podcast An Ai Powered Solution

Apr 22, 2025