Breaking The Chains: How Electric Motor Technology Can Diversify Supply

Table of Contents

Reduced Reliance on Specific Geographic Regions

The concentration of combustion engine manufacturing in a few key regions creates choke points in the global supply chain. Electric motor technology offers a powerful antidote to this vulnerability.

Decentralized Manufacturing

Electric motor manufacturing is becoming increasingly decentralized. This shift towards regional supply chains and localized production offers several key advantages:

- Emerging Manufacturing Hubs: Countries like China, India, and several European nations are rapidly expanding their electric motor manufacturing capabilities, creating a more diverse and resilient global landscape.

- Regional Production Hubs: Establishing regional production hubs reduces reliance on single-sourcing countries, mitigating the risk of disruptions caused by political instability or natural disasters. This "near-shoring" strategy significantly reduces transportation costs and lead times.

- Reduced Transportation Costs and Lead Times: Localized production means shorter transportation distances, lower shipping costs, and faster delivery times, leading to increased efficiency and agility within the supply chain.

The development of robust electric motor manufacturing capabilities within numerous regions signifies a crucial step towards building more resilient regional supply chains and bolstering localized production.

Wider Range of Raw Materials

Electric motors require a broader range of raw materials compared to internal combustion engines. This inherent raw material diversification enhances supply chain resilience.

- Material Comparison: Combustion engines heavily rely on rare earth elements and specific metals, creating vulnerability to price fluctuations and supply disruptions. Electric motors utilize a wider array of more readily available materials like copper, aluminum, and steel.

- Benefits of Diversification: This broader base of materials reduces dependence on any single resource, minimizing the impact of supply shocks and price volatility.

- Increased Resilience to Supply Shocks: A diversified supply of electric motor components creates a more robust and adaptable supply chain, capable of weathering unforeseen disruptions.

Enhanced Technological Independence

Electric motor technology fosters technological independence through collaborative efforts and adaptable designs.

Open-Source Designs and Collaboration

The rise of open-source designs and collaborative development in the electric motor sector is democratizing innovation and reducing reliance on proprietary technologies.

- Open-Source Projects: Several initiatives focus on sharing electric motor designs and improving manufacturing processes. This fosters widespread adoption and reduces dependence on specific manufacturers.

- Benefits of Collaborative Development: Collaboration accelerates innovation, improves design efficiency, and reduces the risk of technological lock-in associated with proprietary systems.

- Fostering Technological Independence: Open-source electric motors empower nations and companies to develop their own capabilities, fostering technological sovereignty and reducing vulnerabilities to external pressures.

Increased Technological Adaptability

Modular designs are becoming increasingly common in electric motor manufacturing. This modularity enhances the adaptability of electric motor technology.

- Advantages of Modular Design: Modular designs allow for easier upgrades, repairs, and customization. This adaptability simplifies maintenance and reduces downtime, crucial for smooth supply chain operations.

- Ease of Maintenance and Repair: The ease of replacing individual modules reduces reliance on specialized technicians and speeds up repair processes.

- Faster Adaptation to Evolving Technological Demands: Modular designs facilitate rapid adaptation to new technologies and evolving market demands, improving the supply chain agility and responsiveness of manufacturers.

Boosting Sustainability and Reducing Environmental Impact

Electric motor technology significantly contributes to creating more environmentally friendly and sustainable supply chains.

Sustainable Manufacturing Practices

The manufacturing process for electric motors presents opportunities for more environmentally friendly practices.

- Eco-Friendly Manufacturing Techniques: Innovations in manufacturing, such as using recycled materials and reducing energy consumption, contribute to a smaller carbon footprint.

- Reduced Carbon Footprint: Electric motor production inherently generates less greenhouse gas emissions compared to the production of combustion engines.

- Improved Resource Efficiency: More efficient manufacturing processes, along with the use of recycled materials, enhance resource utilization and reduce waste. Producing sustainable electric motors is a key driver of eco-friendly supply chains.

Reduced Transportation Emissions

Electric vehicles powered by electric motors dramatically reduce transportation emissions throughout the supply chain.

- Comparison of Transportation Emissions: Electric vehicles produce significantly fewer emissions than vehicles powered by internal combustion engines, reducing the environmental impact of transporting goods and components.

- Benefits of Reduced Reliance on Fossil Fuels: The shift towards electric vehicles lowers overall dependence on fossil fuels, contributing to a cleaner and more sustainable transportation sector.

- Positive Environmental Impact: The widespread adoption of electric vehicle technology and the electric motors driving them represents a crucial step toward creating sustainable transportation and a lower environmental impact across the entire supply chain.

Conclusion

Electric motor technology is reshaping global supply chains, offering a pathway to greater resilience and sustainability. By reducing reliance on specific geographical regions and fostering technological independence, electric motors are creating more robust and adaptable supply networks. Furthermore, the inherent sustainability benefits of electric motor technology contribute to a greener and more environmentally conscious approach to manufacturing and transportation. The key takeaways are clear: decreased geographical dependence, enhanced technological independence, and significantly improved sustainability. Invest in electric motor technology; explore the benefits of electric motor diversification; learn more about the future of sustainable supply chains powered by electric motor technology.

Featured Posts

-

Lizzos In Real Life Tour Ticket Prices And Where To Buy

May 05, 2025

Lizzos In Real Life Tour Ticket Prices And Where To Buy

May 05, 2025 -

Nhl Standings Update Key Games On Showdown Saturday

May 05, 2025

Nhl Standings Update Key Games On Showdown Saturday

May 05, 2025 -

Public Reaction To Lizzos Comparison Of Britney Spears And Janet Jackson

May 05, 2025

Public Reaction To Lizzos Comparison Of Britney Spears And Janet Jackson

May 05, 2025 -

Upcoming Workforce Reductions At The Transportation Department A May Timeline

May 05, 2025

Upcoming Workforce Reductions At The Transportation Department A May Timeline

May 05, 2025 -

Increased Birth Control Access Examining The Post Roe Otc Landscape

May 05, 2025

Increased Birth Control Access Examining The Post Roe Otc Landscape

May 05, 2025

Latest Posts

-

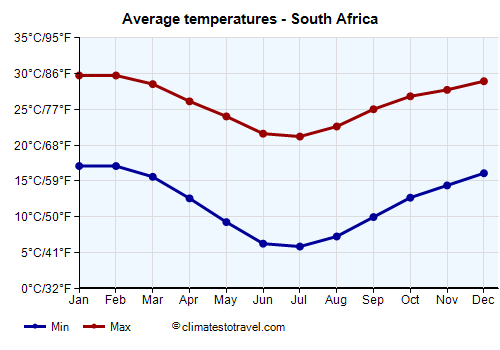

Rising Temperatures In South Bengal Holi Brings Near 38 C Heat

May 05, 2025

Rising Temperatures In South Bengal Holi Brings Near 38 C Heat

May 05, 2025 -

Anna Kendricks Iconic 3 Word Take On Blake Lively

May 05, 2025

Anna Kendricks Iconic 3 Word Take On Blake Lively

May 05, 2025 -

Anna Kendricks Blake Lively Comment Fans Obsessed

May 05, 2025

Anna Kendricks Blake Lively Comment Fans Obsessed

May 05, 2025 -

Another Simple Favor Premiere Anna Kendricks Comments Spark Lively Speculation

May 05, 2025

Another Simple Favor Premiere Anna Kendricks Comments Spark Lively Speculation

May 05, 2025 -

Get Anna Kendricks Look The Perfect Glittering Shell Crop Top For Summer

May 05, 2025

Get Anna Kendricks Look The Perfect Glittering Shell Crop Top For Summer

May 05, 2025