Dysprosium Shortage: A Looming Crisis For Electric Vehicle Production

Table of Contents

The Critical Role of Dysprosium in EV Motors

Dysprosium is a crucial component in the manufacturing of high-performance electric vehicles. Its primary function lies within the powerful neodymium magnets that drive electric motors. Without sufficient dysprosium, the EV revolution could significantly slow down.

Dysprosium in Neodymium Magnets

Neodymium magnets are essential for the efficient operation of electric vehicle motors. These magnets are responsible for generating the torque needed for acceleration and power. However, these magnets are susceptible to demagnetization at high temperatures, a significant challenge in the demanding environment of an EV motor. This is where dysprosium plays a critical role:

- Dysprosium improves the magnets' resistance to demagnetization at high temperatures, ensuring efficient and consistent motor operation, even under stress.

- Increased demand for neodymium magnets, driven by the booming EV market, directly translates to increased demand for dysprosium. This escalating demand is outpacing current supply, creating the current shortage.

- Alternative magnet materials are currently less efficient and often more costly, making them a less attractive option for mass-market EV production. The performance trade-off is significant.

The Impact on Motor Efficiency and Performance

A dysprosium deficiency would have a direct and negative impact on EV motor performance and efficiency:

- Reduced dysprosium content compromises magnet performance, potentially impacting range and acceleration. Drivers could experience shorter driving distances and less responsive acceleration.

- This could lead to higher manufacturing costs and reduced consumer appeal, making EVs less competitive compared to internal combustion engine vehicles. The cost increase could impact affordability and market penetration.

Geographic Concentration and Supply Chain Vulnerabilities

The global supply of dysprosium is heavily concentrated, creating significant vulnerabilities in the EV supply chain.

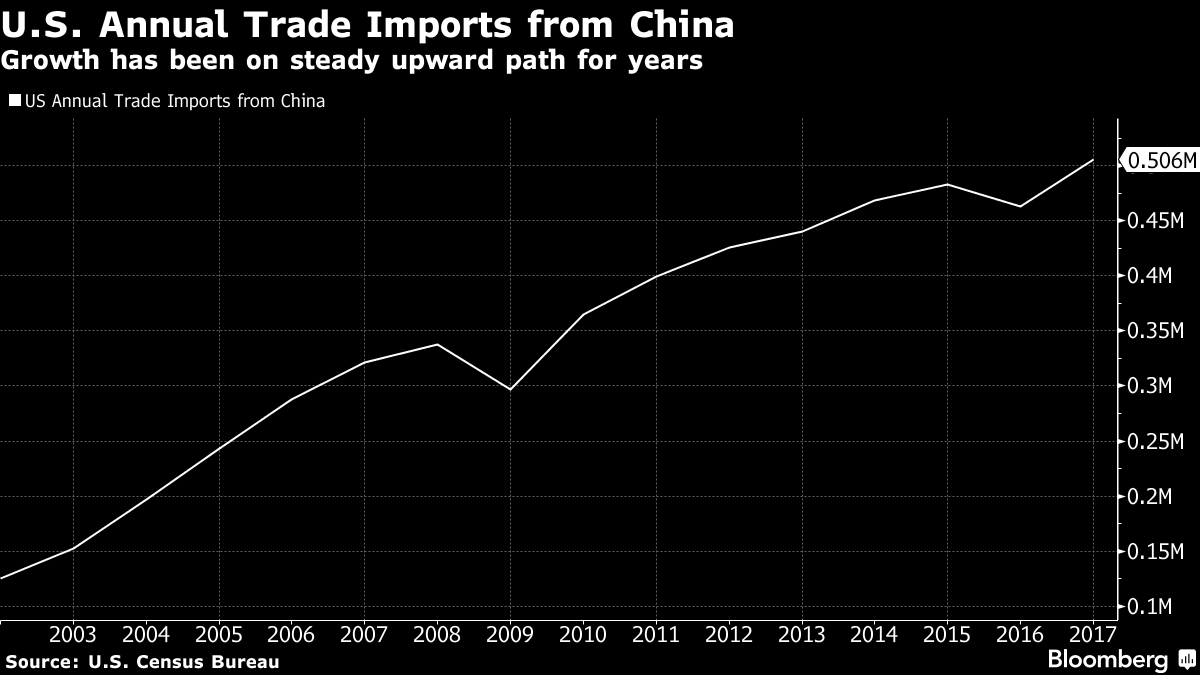

China's Dominance in Dysprosium Production

China holds a near-monopoly on dysprosium mining and processing. This dominance presents several significant risks:

- Geopolitical instability and trade disputes could severely disrupt the supply of dysprosium, leading to production halts and price spikes. This dependence represents a major geopolitical risk.

- Dependence on a single source creates vulnerability to price manipulation and supply interruptions, giving China significant leverage over the global EV market. This concentration of power necessitates diversification.

The Challenges of Diversification and Sustainable Sourcing

Diversifying dysprosium sources and establishing sustainable mining practices are crucial but face significant hurdles:

- Exploration and development of new dysprosium deposits require significant investment and time, making it a long-term solution that needs immediate attention.

- Emphasis on ethical and environmentally friendly mining practices is crucial for long-term sustainability, ensuring responsible resource extraction without harming local communities or the environment. This includes minimizing environmental impact and promoting fair labor practices.

Potential Solutions and Mitigation Strategies

Addressing the dysprosium shortage requires a multi-pronged approach involving technological innovation, improved recycling, and supportive government policies.

Exploring Alternative Magnet Technologies

Significant research and development efforts are focused on alternative magnet materials that require less or no dysprosium:

- Investment in research and development of dysprosium-free or reduced-dysprosium magnets is critical for long-term sustainability and supply chain security.

- Focus on improving the efficiency and cost-effectiveness of these alternative materials is essential for widespread adoption in the EV industry.

Improving Recycling and Resource Recovery

Recycling dysprosium from end-of-life EV components and electronic waste is crucial:

- Efficient recycling processes can significantly reduce reliance on new mining operations, offering a sustainable solution to the resource scarcity.

- Technological advancements are needed to improve the efficiency of dysprosium extraction from recycled materials, making the recycling process economically viable and scalable.

Government Policies and Incentives

Governments play a vital role in fostering solutions to the dysprosium shortage:

- Investment in research and development grants for alternative magnet technologies can accelerate the transition to dysprosium-independent solutions.

- Tax credits and subsidies for responsible dysprosium mining and recycling can incentivize sustainable practices and promote domestic resource development.

Conclusion

The dysprosium shortage represents a serious challenge to the future of electric vehicle production. Addressing this critical issue requires a multifaceted approach, encompassing investment in alternative magnet technologies, improvements in recycling processes, and strategic government policies. Failure to act decisively could significantly impede the transition to sustainable transportation. We must proactively address the looming dysprosium shortage to ensure the continued growth and success of the electric vehicle industry. Understanding the challenges and embracing innovative solutions is essential to avert this potential crisis and pave the way for a greener future powered by sustainable EV technology. Let's work together to find innovative solutions for a secure and sustainable future for electric vehicles.

Featured Posts

-

The Long Term Consequences Of Trumps China Tariffs On Us Economic Growth

Apr 29, 2025

The Long Term Consequences Of Trumps China Tariffs On Us Economic Growth

Apr 29, 2025 -

Shedeur Sanders Prank Call Son Of Falcons Defensive Coordinator Apologizes

Apr 29, 2025

Shedeur Sanders Prank Call Son Of Falcons Defensive Coordinator Apologizes

Apr 29, 2025 -

Capital Summertime Ball 2025 At Wembley Stadium Your Complete Guide

Apr 29, 2025

Capital Summertime Ball 2025 At Wembley Stadium Your Complete Guide

Apr 29, 2025 -

Your Guide To Capital Summertime Ball 2025 Tickets Braintree And Witham

Apr 29, 2025

Your Guide To Capital Summertime Ball 2025 Tickets Braintree And Witham

Apr 29, 2025 -

Helena Och Iva Oegonvittnen Till Skolskjutningen

Apr 29, 2025

Helena Och Iva Oegonvittnen Till Skolskjutningen

Apr 29, 2025