How U.S. Companies Are Responding To Tariff Uncertainty Through Cost Reduction

Table of Contents

Optimizing Supply Chains for Cost Reduction

A robust and resilient supply chain is paramount in navigating tariff uncertainty. Optimizing this network for cost reduction involves several key strategies:

Reshoring and Nearshoring

The trend of reshoring (bringing manufacturing back to the U.S.) and nearshoring (moving it to nearby countries) is gaining momentum. This reduces reliance on tariff-affected regions and offers several potential advantages.

- Benefits: Reduced transportation costs, shorter lead times, improved supply chain visibility, enhanced control over quality, and potential access to government incentives for domestic manufacturing.

- Drawbacks: Higher labor costs in some cases, potential challenges in finding skilled labor, and the need for significant upfront investment in new facilities or equipment.

- Examples: Several apparel companies have begun reshoring production to reduce their dependence on imports from countries with high tariffs. Similarly, some electronics manufacturers have neared shored their operations to Mexico to lessen reliance on Asian supply chains.

This strategic shift in supply chain location is a key component of effective cost reduction in a volatile global trade environment. The keyword here is supply chain optimization, focusing on the reduction of import costs through domestic or regional manufacturing.

Diversifying Suppliers

Relying on a single supplier exposes businesses to significant risk. Supplier diversification, a cornerstone of cost reduction and risk mitigation, involves sourcing materials and components from multiple suppliers across different geographical locations.

- Importance: Diversification protects against disruptions caused by tariffs, political instability, natural disasters, or supplier-specific issues.

- Challenges: Finding reliable alternative suppliers requires thorough due diligence, including assessing supplier capabilities, financial stability, and ethical practices.

- Practical Tips: Conduct comprehensive market research, establish strong supplier relationships, implement robust supplier performance management systems, and build in flexibility into contracts.

By diversifying your sourcing strategy, you create a more resilient and cost-effective global sourcing network and enhance your overall supply chain resilience.

Negotiating Better Terms with Suppliers

Strong supplier relationships are invaluable. Effective negotiation can unlock significant cost reduction opportunities.

- Importance: Negotiating favorable pricing, payment terms, and delivery schedules can significantly impact profitability.

- Strategies for Effective Negotiation: Build rapport with your suppliers, clearly articulate your needs and expectations, present a strong case for better terms, explore alternative payment options such as extended payment terms or early payment discounts, and always seek win-win solutions.

Strategic supplier negotiation, combined with effective supplier relationship management, is a crucial aspect of proactive cost reduction.

Implementing Internal Cost Reduction Strategies

Beyond supply chain optimization, internal strategies play a vital role in achieving significant cost reduction.

Streamlining Operations

Improving operational efficiency is key to reducing waste and maximizing productivity.

- Process Optimization: Analyze existing processes to identify bottlenecks, inefficiencies, and areas for improvement.

- Automation: Automate repetitive tasks to improve speed, accuracy, and consistency, reducing labor costs and human error.

- Examples: Implementing lean manufacturing principles, optimizing inventory management systems, and using technology to automate data entry processes.

These improvements drive significant cost reduction by enhancing operational efficiency and minimizing waste reduction.

Technology Adoption and Automation

Leveraging technology for cost reduction is crucial for competitiveness.

- Productivity Improvement: Investing in technologies such as artificial intelligence (AI), machine learning (ML), and robotics can dramatically boost productivity and reduce labor costs.

- Specific Applications: AI-powered systems can optimize processes, predict demand, and improve decision-making. Robotics can automate repetitive tasks in manufacturing and warehousing. ML algorithms can improve forecasting accuracy and reduce inventory levels.

Strategic technology adoption leads to significant cost reduction by enhancing efficiency and automating tasks.

Inventory Management and Optimization

Effective inventory management is critical for minimizing storage costs and preventing obsolescence.

- Just-in-Time (JIT) Inventory: A JIT system minimizes inventory holding costs by receiving materials only when needed.

- Demand Forecasting: Accurate demand forecasting helps optimize inventory levels, reducing the risk of stockouts or excess inventory.

- Supply Chain Visibility: Enhanced visibility across the supply chain allows for better planning and control of inventory levels.

Through techniques like inventory optimization, companies can achieve substantial cost reduction by improving supply chain visibility and minimizing storage costs.

Utilizing Government Resources and Support for Cost Reduction

Several government programs and incentives are available to support businesses facing tariff challenges.

- Government Assistance: Explore options like tax incentives, grants, and small business support programs offered at the federal, state, and local levels.

- Tariff Relief: Investigate whether your industry or products are eligible for any tariff relief or mitigation programs.

Make use of available resources to lessen the impact of tariffs and facilitate cost reduction strategies. For specific programs and links, consult the relevant government websites (links to be inserted here based on current offerings).

Conclusion: Mitigating Tariff Uncertainty Through Effective Cost Reduction

In conclusion, mitigating the impact of tariff uncertainty requires a proactive approach centered on cost reduction. By optimizing supply chains through reshoring, nearshoring, and supplier diversification; implementing internal cost reduction strategies such as streamlining operations, technology adoption, and inventory management; and leveraging available government resources, U.S. companies can enhance their resilience and competitiveness in the global market. Implementing sustainable cost reduction strategies offers long-term benefits, ensuring profitability and success even amidst economic uncertainty. Start your journey toward effective cost reduction today! Assess your current cost structures, explore the strategies discussed above, and develop a comprehensive plan to mitigate the impact of tariff uncertainty and secure your business's future.

Featured Posts

-

Remembering The 2012 Louisville Tornado Impacts And Recovery

Apr 29, 2025

Remembering The 2012 Louisville Tornado Impacts And Recovery

Apr 29, 2025 -

Understanding The Rise Of Older Viewers On You Tube Data From Npr

Apr 29, 2025

Understanding The Rise Of Older Viewers On You Tube Data From Npr

Apr 29, 2025 -

Open Thread Community February 16 2025

Apr 29, 2025

Open Thread Community February 16 2025

Apr 29, 2025 -

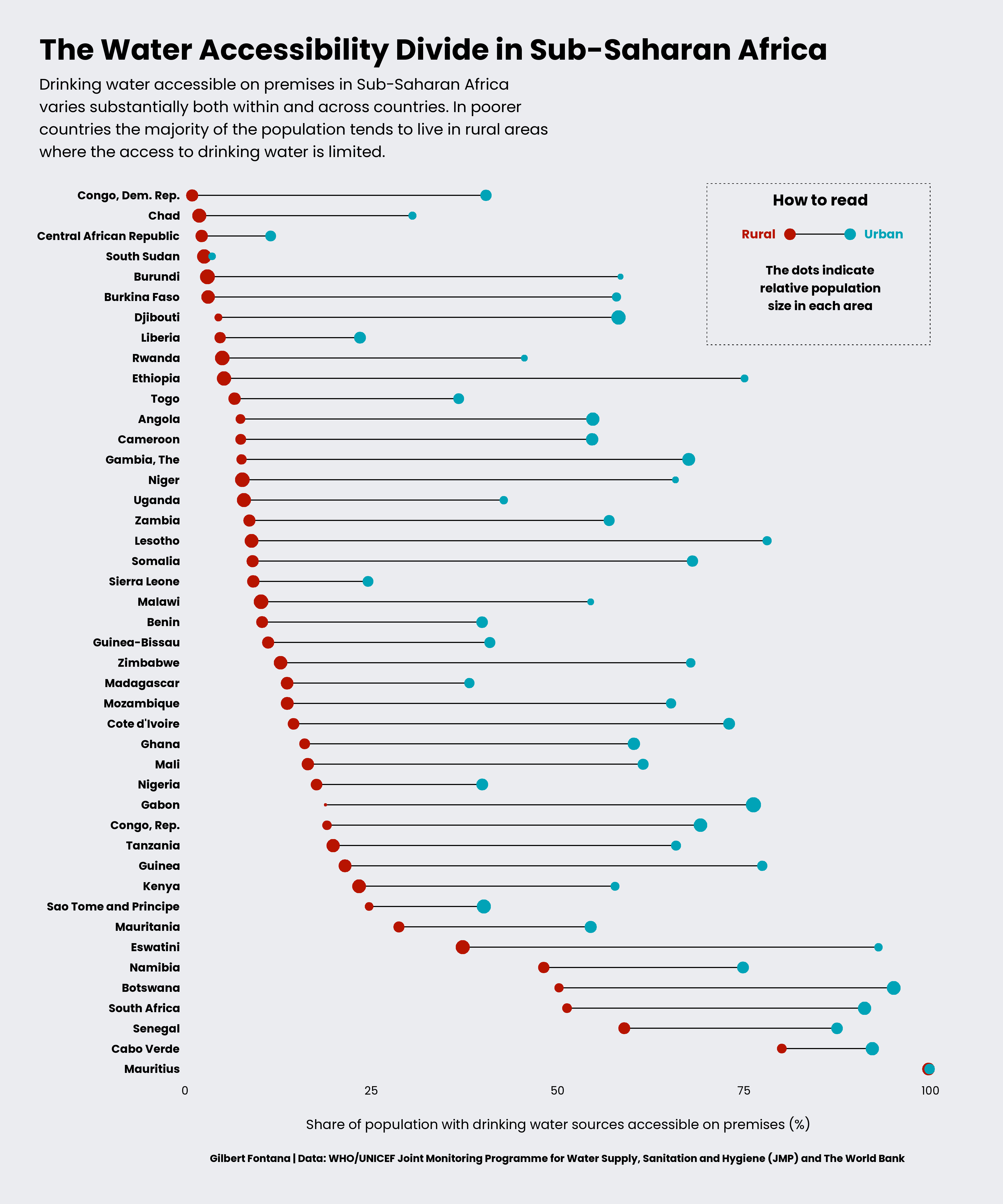

Pw Cs Retreat From Sub Saharan Africa A Nine Country Case Study

Apr 29, 2025

Pw Cs Retreat From Sub Saharan Africa A Nine Country Case Study

Apr 29, 2025 -

Us Attorney Generals Warning To Minnesota Compliance With Transgender Athlete Ban

Apr 29, 2025

Us Attorney Generals Warning To Minnesota Compliance With Transgender Athlete Ban

Apr 29, 2025