Overcoming The Technological Barriers To Robotic Nike Sneaker Manufacturing

Table of Contents

Precision and Dexterity Challenges in Robotic Assembly

Sneaker assembly is an intricate process involving delicate stitching, precise gluing, and careful placement of numerous components: uppers, midsoles, outsoles, laces, and more. Replicating the dexterity of a human hand in this process poses a significant challenge for robotics.

- Difficulty replicating human dexterity: Tasks like threading laces or precisely placing small components require a level of fine motor control that current robots struggle to achieve. The subtle nuances of manipulating different materials and textures present a significant hurdle.

- Need for advanced sensors and AI: Real-time adjustments and quality control are essential. Advanced sensors, coupled with artificial intelligence, are necessary to ensure consistent accuracy and identify defects during assembly. Computer vision systems play a crucial role in this process.

- Limitations of current robotic grippers: Existing robotic grippers often struggle to handle the diverse materials and shapes found in sneaker construction. Leather, synthetics, and rubber each require different gripping techniques.

To overcome these challenges, researchers and engineers are developing advanced robotic grippers incorporating tactile sensors. These sensors provide robots with a "sense of touch," enabling them to manipulate objects with greater precision and adapt to variations in material properties. Successful integration of these technologies is slowly but surely increasing the efficiency of automated sneaker assembly. For example, some manufacturers are using robotic systems for specific tasks like applying adhesive or attaching certain components, demonstrating the potential of targeted automation.

Material Handling and Supply Chain Integration

Automating material handling within a sneaker factory is another significant hurdle. Efficiently managing the flow of diverse materials—leather, synthetics, rubber, threads, and other components—to robotic workstations is crucial for seamless production.

- Efficient material movement: The system must efficiently move diverse materials to the correct robotic workstations at the precise moment they are needed, minimizing delays and downtime.

- Supply chain integration: Seamless integration with existing supply chains and inventory management systems is critical. This requires sophisticated software and data analytics to track materials, predict demand, and optimize inventory levels.

- Consistent material flow: Minimizing disruptions is key to maintaining high productivity. Any bottleneck in the material flow can significantly impact the overall efficiency of the robotic assembly line.

Innovative solutions, such as automated guided vehicles (AGVs) and robotic arms, are being implemented to address these challenges. AGVs autonomously transport materials between different workstations, while robotic arms precisely position materials for robotic assembly. AI-powered predictive maintenance plays a crucial role in minimizing disruptions by predicting potential equipment failures and scheduling maintenance proactively. This proactive approach to maintenance reduces downtime and ensures a smoother, more efficient workflow.

Programming and Software Complexity

Programming and controlling robotic arms and other automated systems for sneaker manufacturing is incredibly complex. The software must be adaptable, user-friendly, and robust enough to handle variations in sneaker models and manufacturing processes.

- Adapting to different models: The software needs to be easily adaptable to different sneaker models, sizes, and designs without requiring extensive reprogramming. This requires flexible and modular software architectures.

- User-friendly interfaces: Intuitive interfaces are essential for operators to easily manage and reprogram robotic systems. Complex programming languages should be abstracted away to allow for easier operation and maintenance.

- Advanced simulation software: Advanced simulation software allows engineers to test and optimize robotic systems before deployment, reducing the time and cost associated with troubleshooting and adjustments.

Collaborative robots (cobots) offer a promising solution by working safely alongside human workers. Cobots can handle repetitive or physically demanding tasks, freeing up human workers to focus on more complex or creative aspects of the manufacturing process. This collaborative approach leverages the strengths of both human dexterity and robotic precision.

Cost and Return on Investment (ROI)

Implementing robotic systems in sneaker manufacturing represents a significant upfront investment. The high initial cost is a major barrier for many companies.

- High initial costs: The cost includes robotic arms, sensors, software, integration, and training.

- Training costs: Personnel need training to operate and maintain the robotic systems effectively.

- Long-term cost savings: While significant initial investments are necessary, the potential for increased efficiency and reduced labor costs over the long term makes this a financially viable strategy.

Analyzing the long-term ROI is crucial. Rising labor costs and increasing demand for Nike sneakers create a compelling case for automation. Furthermore, government incentives and grants supporting automation initiatives can help offset the initial investment. The potential for increased production volume and consistent product quality ultimately outweighs the high initial costs, provided a thorough analysis and planning are performed.

Ethical and Social Implications

Automating sneaker manufacturing raises ethical and social concerns, primarily concerning job displacement.

- Workforce retraining: Investing in workforce retraining and upskilling programs is crucial to prepare workers for new roles within the automated factory environment. These programs should focus on robotics maintenance, programming, and data analysis.

- New job creation: Automation creates new job opportunities in robotics engineering, maintenance, and programming. These new roles often require higher skill levels and offer greater earning potential.

- Social impact: It's important to consider the social impact of automation on the workforce and to mitigate any negative consequences through thoughtful planning and implementation.

Despite potential job displacement in some areas, robotic automation can also improve working conditions by reducing repetitive strain injuries and creating a safer work environment. This improved worker safety and well-being are significant benefits to consider when implementing robotic automation solutions.

Conclusion

Overcoming the technological barriers to robotic Nike sneaker manufacturing presents significant challenges, but also remarkable opportunities. From advanced robotic grippers to AI-powered material handling, innovative solutions are gradually transforming this traditionally labor-intensive industry. While the initial investment is substantial, the long-term potential for increased efficiency, reduced costs, and improved working conditions makes investing in robotic solutions a worthwhile endeavor. Embracing robotic Nike sneaker manufacturing is crucial for remaining competitive in a rapidly evolving global market. Companies must proactively address the ethical implications and invest in workforce development programs to reap the full benefits of this technological advancement. The future of Nike sneaker manufacturing may very well be robotic, and it's a future worth actively shaping through continued innovation and strategic implementation of robotic technologies.

Featured Posts

-

Cocaine At White House Secret Service Ends Investigation

Apr 22, 2025

Cocaine At White House Secret Service Ends Investigation

Apr 22, 2025 -

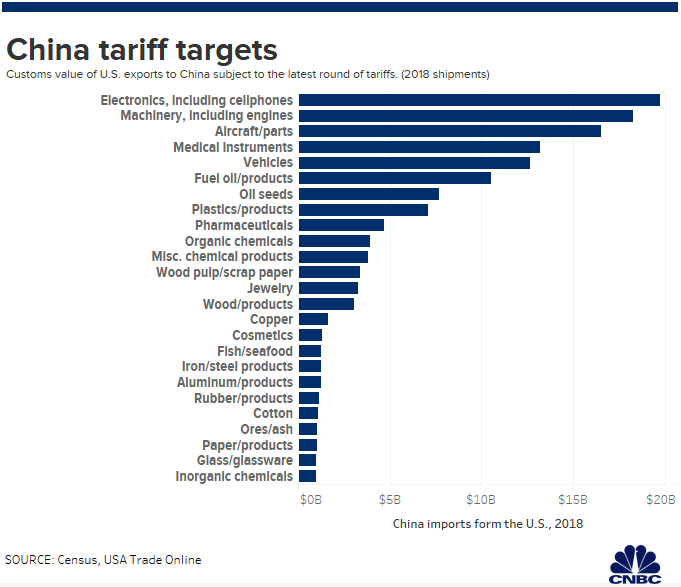

Export Led Growth Assessing Chinas Tariff Sensitivity

Apr 22, 2025

Export Led Growth Assessing Chinas Tariff Sensitivity

Apr 22, 2025 -

Wall Streets Flight To Safety Why Netflix Thrives In The Big Tech Downturn

Apr 22, 2025

Wall Streets Flight To Safety Why Netflix Thrives In The Big Tech Downturn

Apr 22, 2025 -

Saudi Aramco And Byd A New Ev Technology Partnership

Apr 22, 2025

Saudi Aramco And Byd A New Ev Technology Partnership

Apr 22, 2025 -

Trump Administration To Slash Another 1 Billion In Harvard Funding

Apr 22, 2025

Trump Administration To Slash Another 1 Billion In Harvard Funding

Apr 22, 2025