The Critical Role Of Dysprosium In Electric Vehicle Motors And Its Supply Chain Challenges

Table of Contents

Dysprosium's Importance in Electric Vehicle Motor Performance

Enhancing Magnet Properties:

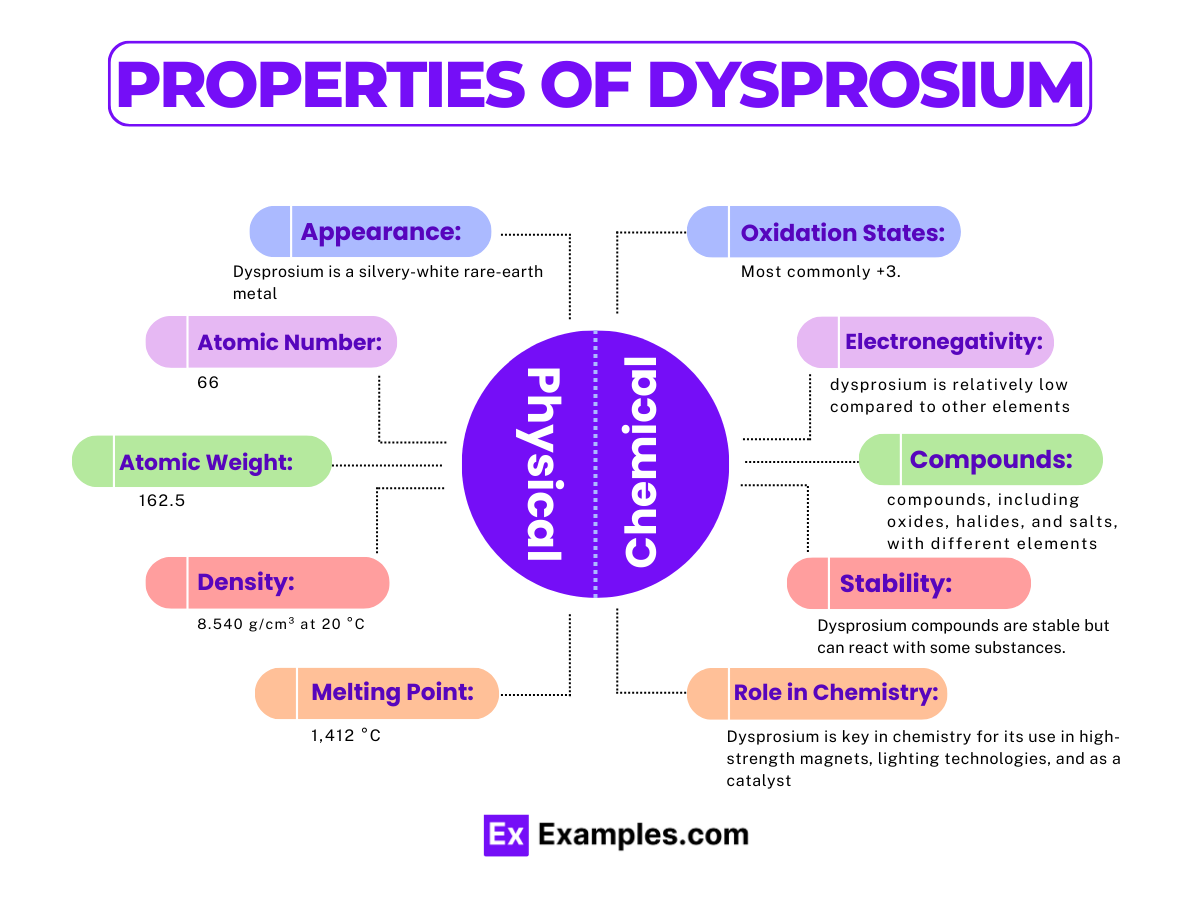

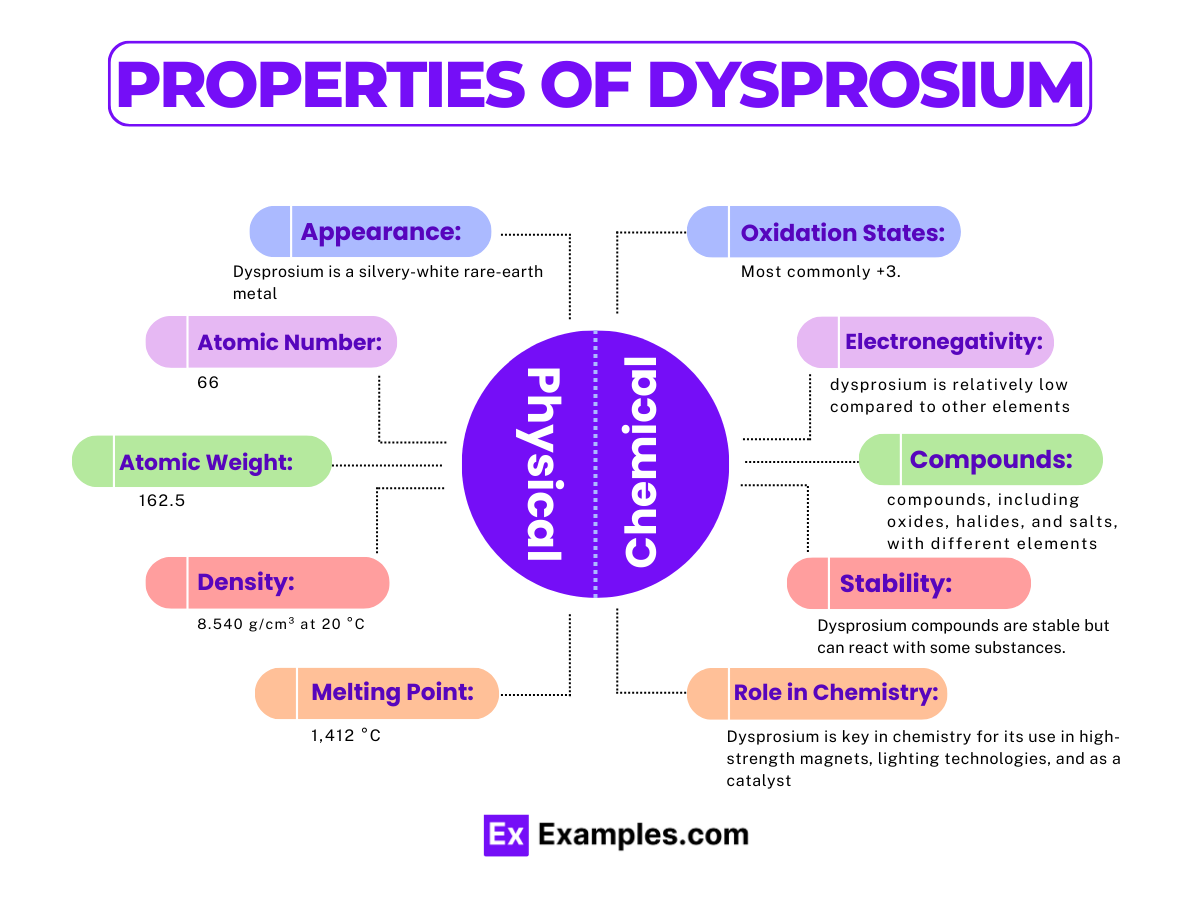

Dysprosium's unique magnetic properties, specifically its high coercivity, are essential for preventing demagnetization in high-temperature and high-power applications. This is crucial for EV motors operating under demanding conditions, such as those found in high-performance EVs and hybrid electric vehicles (HEVs). Its presence is critical for maintaining the motor's strength and efficiency even under significant stress.

- Improved thermal stability: Dysprosium significantly improves the thermal stability of neodymium magnets, preventing performance degradation at elevated temperatures.

- Reduced motor size and weight: The enhanced magnetic properties allow for the use of smaller and lighter magnets, contributing to overall vehicle weight reduction and improved energy efficiency.

- Increased motor efficiency: Higher efficiency magnets translate to less energy loss and improved overall range for electric vehicles.

- Enhanced power output: Dysprosium-enhanced magnets enable higher torque and power output from the electric motor, leading to improved acceleration and performance.

Comparison with other rare earth elements:

While other rare earth elements like neodymium are also vital components of these powerful magnets, dysprosium's contribution to high-temperature performance is unparalleled. Neodymium magnets alone are susceptible to demagnetization at higher operating temperatures, leading to decreased motor performance and potential failure. Dysprosium mitigates this significantly.

- Dysprosium's role in reducing the risk of demagnetization at higher temperatures: This extends the lifespan of the motor and ensures consistent performance under various operating conditions.

- Higher energy density compared to alternatives: Dysprosium's inclusion allows for a higher energy density in the magnets, contributing to a more compact and powerful motor design. This is crucial for maximizing range and performance in EVs.

The Geopolitical and Environmental Challenges of Dysprosium Supply

Concentrated Sourcing and Geopolitical Risks:

A significant portion of the world's dysprosium supply is concentrated in a few countries, primarily China. This geographic concentration creates significant geopolitical risks, making the dysprosium supply chain vulnerable to disruptions.

- China's dominance in rare earth mining and processing: China controls a significant portion of the global rare earth mining and processing capacity, leading to concerns about potential supply restrictions or price manipulation.

- Potential for export restrictions or price manipulation: Geopolitical tensions or trade disputes could easily lead to export restrictions or price hikes, significantly impacting the EV industry.

- Dependence on a single source of supply creating vulnerability: This over-reliance on a single nation for such a critical material presents a significant vulnerability for the global electric vehicle market.

Environmental Concerns of Dysprosium Mining and Processing:

The mining and processing of dysprosium, like other rare earth elements, can have significant environmental impacts. These impacts necessitate a focus on sustainable and responsible mining practices.

- Water usage in the extraction process: Rare earth mining is water-intensive, potentially straining local water resources.

- Waste generation and disposal challenges: The mining and processing of dysprosium generates significant waste, posing environmental challenges related to waste disposal and remediation.

- The carbon footprint of mining and refining: The entire process, from mining to refining, contributes significantly to greenhouse gas emissions, highlighting the need for more sustainable approaches.

Strategies for Mitigating Dysprosium Supply Chain Risks

Diversification of Supply Sources:

Exploring and developing alternative sources of dysprosium is crucial to reduce reliance on a single nation. This necessitates investment in exploration and development in other countries with dysprosium reserves.

- Investment in exploration and mining in other regions: Increased exploration efforts in countries with dysprosium deposits are needed to create a more diverse supply chain.

- Fostering international collaboration: Collaboration between nations is crucial to share knowledge, technology, and resources, ensuring a stable and secure supply.

- Supporting responsible mining practices in new sources: New mining operations must prioritize environmentally responsible practices to minimize the negative impacts on the environment and local communities.

Technological Innovation and Material Substitution:

Research into alternative magnet materials and designs that require less or no dysprosium is essential for long-term supply security. This includes exploring less rare-earth-dependent motor designs and exploring alternative materials.

- Development of dysprosium-reduced magnets: Research and development efforts focused on creating high-performance magnets with reduced dysprosium content are crucial.

- Exploring alternative materials like ferrite magnets (though with lower performance): While ferrite magnets offer a less performant alternative, they represent a potential pathway to reduce reliance on rare earths.

- Advancements in motor design and control: Innovations in motor design and control systems can help mitigate the need for high-performance, dysprosium-rich magnets.

Recycling and Reuse of Dysprosium:

Implementing effective recycling programs for end-of-life EV motors is crucial to recover valuable dysprosium and reduce reliance on primary mining.

- Development of efficient and cost-effective recycling technologies: Investment in research and development of efficient and economically viable recycling technologies is essential.

- Establishing clear guidelines for responsible recycling: Clear regulations and guidelines for the responsible recycling of EV components are necessary to ensure the safe and effective recovery of rare earth elements.

- Incentivizing the recovery of rare earth elements: Government policies and incentives can encourage and support the development and implementation of effective recycling programs.

Conclusion:

Dysprosium plays a crucial role in the performance of electric vehicle motors, but its limited supply and concentrated geographic sourcing pose significant challenges to the future of the EV industry. Addressing these issues requires a multi-faceted approach including diversification of supply sources, technological innovation, and the implementation of effective recycling programs. By proactively addressing the dysprosium supply chain challenge, we can pave the way for a more sustainable and secure future for electric vehicle technology. Investing in research, responsible mining practices, and recycling initiatives is vital to ensuring the long-term viability of dysprosium and the continued growth of the electric vehicle market. Let's work together to build a resilient dysprosium supply chain for the future of electric mobility.

Featured Posts

-

Rebecca Lobach Black Hawk Crash And The Fatal Decision To Disregard Co Pilot

Apr 29, 2025

Rebecca Lobach Black Hawk Crash And The Fatal Decision To Disregard Co Pilot

Apr 29, 2025 -

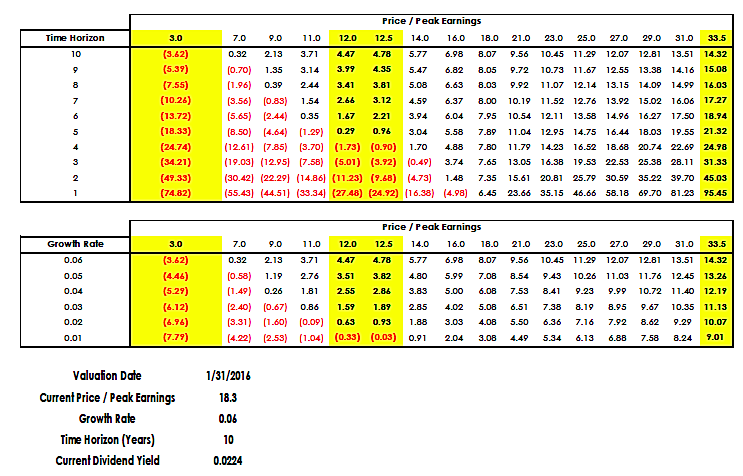

Bof As Take Why Stretched Stock Market Valuations Shouldnt Worry Investors

Apr 29, 2025

Bof As Take Why Stretched Stock Market Valuations Shouldnt Worry Investors

Apr 29, 2025 -

Canada Election Carneys Final Campaign Push Faces Headwinds

Apr 29, 2025

Canada Election Carneys Final Campaign Push Faces Headwinds

Apr 29, 2025 -

Black Hawk Pilot Failed To Follow Instructors Commands Dc Crash Investigation

Apr 29, 2025

Black Hawk Pilot Failed To Follow Instructors Commands Dc Crash Investigation

Apr 29, 2025 -

Jeff Goldblums Oscar Photo Check Goes Viral Internet Reacts Hes Just Like Us

Apr 29, 2025

Jeff Goldblums Oscar Photo Check Goes Viral Internet Reacts Hes Just Like Us

Apr 29, 2025